Many courier companies hit the same crossroad sooner or later: Is it better to continue as a single depot operation, or is it time to expand to a multi-depot approach?

This isn’t an easy decision to make and the driving factor isn’t always growth. For many courier companies, it might be that the cost and complexity have started to outweigh the benefits of having a single depot.

But anyone who’s tried it knows that expansion isn’t just opening another building and hoping for the best. You’re essentially doubling your day-to-day operations, which comes with its own set of challenges.

Mark Whelan, Logistics Manager at Express Logistics sums up the dilemma perfectly: “Once we start sending vans two hours outside our province before they even begin deliveries, you have to ask if we need a new depot, or is it worth taking on that work?”

And this is the exact balancing act a lot of courier companies face.

One depot is “safe”. It keeps you lean and agile and you’ve got eyes on everything. But stretch that single hub too far and you might find yourself burning through fuel and missing out on region-specific contracts.

This guide is about spotting that tipping point. We’ll look at how far a single depot can take you, the signs it’s time to expand, and what it really takes to run a multi-depot operation.

How far can a single depot take you?

The obvious way to grow is to add more depots. But, if you play it right, you can go a long way with just one. According to Mark, the biggest advantage of staying as a single depot is control because everything happens under the same roof.

“When problems arise, you can nip them in the bud straight away,” says Mark. “If it’s out of sight, it’s easy for issues to slip.”

It’s also easier to keep your operations lean if you’re not having to split staff, budgets, or attention across multiple sites. This kind of agility is a big deal in last mile delivery, where customers continue to have sky-high expectations and even the tiniest of mistakes feels like it’s under a microscope.

Cost control is another bonus. Mark explains that having multiple depots can impact your expenses, causing them to “dramatically increase and even spiral out of control” if you’re not ready for it.

A single site means one rent payment, one set of utilities, and one group of assets to maintain. On top of this, you can avoid (or at least handle) the overhead that comes with replicating all the necessary systems and processes at a second location.

The proof is in the pudding. Plenty of courier companies have scaled with just one central hub. Mark uses PrimeLine Express as an example:

“One of our service partners, PrimeLine Express, has one central hub near Dublin, where they distribute all goods from the EU and UK that come in every morning via the airport or via the ferry terminals along with all the essential business deliveries. They come to that depot around 4am, and then vans from all over Ireland come and take the freight and deliver it that day. So keeping everything in one central hub makes sense for them, because of that same day service.”

Mark Whelan

Logistics Manager, Express Logistics

That model works because PrimeLine’s location has been well thought-out. For one it’s close to Dublin’s airport and ferry terminals, so they can get shipments into the country overnight and their fleet vans out in the morning to cover the whole of Ireland.

Of course, there are limits. A single depot works best when you have a small delivery footprint, so your drivers aren’t spending hours on the road before they start dropping packages. When you’re regularly sending vans far outside your “home turf”, the advantages we’ve just listed start to disappear.

How to recognize the tipping points

Keeping things lean with a single depot might simplify your operation (somewhat), but there comes a time when these benefits change into something that holds you back. At some point, distance, costs, and the quality of service start working against you when you’re trying to do everything from one location.

The tricky part is knowing when it’s time to expand. Here are some key questions to ask that might make the decision for you.

Are your fuel costs spiralling?

The first and most obvious signal is fuel. It’s one of the biggest costs on the books, especially when your vans are spending hours on the road before stop number #1.

“You’ve got to balance it out,” says Mark. “Is it worth wasting two to four hours a day driving, or does it make sense to open a depot closer to that area?”

Those “dead miles” add up super quick, so strategically opening depots to cut down on time spent on the road can be worthwhile in the end.

Are you missing out on big contracts?

Another big trigger is opportunity cost. If you’re in the wrong place, you can automatically write yourself off from lucrative contracts before you’ve even pitched.

“If we’re not in the right area, we can’t even tender for contracts,” says Mark. “We’ll look at the contract, but both sides know there’s no money in it.”

It makes sense. Retailers want a reliable, cost-effective service, so if you’re asking them to pay for hours of extra drive time, it’s really not worth it for them.

Is your existing depot crumbling under the pressure?

If your one and only depot is bursting at the seams with too many vans, drivers, and parcels, it’s a good sign that demand is outgrowing your existing infrastructure. At a certain point, no amount of tweaking your processes will fix the simple fact that the building is too small for the volume you’re handling.

Are the recipients starting to feel it?

The biggest red flag of all is when the recipient starts being impacted. Late deliveries and missed time windows are all symptoms of a network that’s stretched way too thin.

You can get away with a few slip ups here and there, but if there’s a consistent thread of bad reviews, unhappy customers or delivery disputes that bog down your dispatcher, you risk tanking your reputation and losing the very contracts that helped you grow in the first place.

How to read the writing on the wall

These are just a few pivotal moments when courier companies might realize they need to expand, but it’s usually more than one factor that actually makes them take the leap. If you’re missing out on big contracts and dealing with unhappy customers, it’s pretty clear what needs to happen.

The biggest takeaway to note is that expanding works best when it’s a proactive decision, not a reactive scramble. Start planning when you see these signs so you’re not dealing with the aftermath of burnt out drivers and lost contracts.

The risks of expanding too soon

Knowing when to expand and when to stick with what you’ve got is a bit of a balancing act. Yes, waiting too long has its downsides, but so does jumping in too early.

The first and biggest risk is cost. You’re not just paying extra rent on a new depot, you’re also paying for extra staff, new equipment, vehicles, IT, utilities, and everything else that comes with having a whole other building. If your revenue isn’t increasing with those added costs, you can find yourself stretched too thin very quickly.

Another risk is oversight. When you have one hub you can comfortably keep an eye on everything. But as soon as your team is spread across two sites, there’s room for gaps in comms and for standards to slip.

Mark has seen this firsthand and warns against rushing the process:

“I highly recommend considering all options and planning ahead before expanding so you don’t misjudge capacity. You might have a contract in place, or one that you have just acquired, and think, we're going to take on that new warehouse. But that contract could expand to 100% more parcels, and then you've taken on too small a depot, or likewise, they could take 50% of them back, and you're left with too big of a depot.”

Mark Whelan

Logistics Manager at Express Logistics

A similar thing can happen if you try to alleviate the costs by splitting resources between depots. “Spreading your staff too thinly between two depots would mean that you’d suffer overall,” says Mark. “It becomes a money pit if you can’t manage both.”

Misjudging your capacity can be a real problem, especially because we never really know what the future holds. There’s the very real, very scary chance you could open a brand new site only to have your biggest client scale back. Or the opposite happens, where a contract doubles in size overnight and your new depot is too small from day one.

Mark also highlights another danger: leaning too heavily on subcontractors to cover the gaps that growing pains open up.

“We’ve seen first hand companies using subcontractors to run whole depots… within months, customers were complaining, margins collapsed, and the depot failed.”

Mark Whelan

Logistics Manager at Express Logistics

Choosing the right multi-depot model

When you’ve decided it’s time to expand, the next question is: what type of depot setup makes the most sense?

The answer really depends on how far you’re stretching yourself and what kinds of contracts you’re chasing.

Mark suggests two main options:

- Satellite depots

- Full-service depots

Model | Best for |

|---|---|

Satellite depots | Going from one to two depots and testing new areas without it costing too much. |

Full-service depots | Running three or more depots and handling high volumes in multiple areas. |

The satellite model

A satellite depot is basically a carbon copy of your main hub, just on a smaller scale. Parcels go out from your central depot, drivers pick them up at the satellite, and once the morning rush is done, you can shut the site down for the day.

Mark sees this as the most practical option for companies going from one to two depots.

“If you’re going from one to two depots, a satellite is ideal, you just replicate your main depot and shut it once parcels are out. But beyond two, you need full-service depots that can stand on their own.”

Mark Whelan

Logistics Manager at Express Logistics

The biggest advantage of this model is you don’t need to staff the satellite depot around the clock as it’s basically an extension of your existing operation.

The downside is satellites only take you so far. On paper, they look pretty simple, but you’re no longer just dealing with a neat “hub - driver - delivery” system. Suddenly, you’re figuring out which parcels need to go to which satellite and how to stop drivers overlapping each other’s routes.

So, while research shows satellites are a smart way to test new regions and avoid diving headfirst into a full-blown second hub, you still need to keep a close eye on the numbers.

The full-service model

In a full-service model, each site operates like an independent hub, with its own staff, systems, and management. A full-service depot can stand alone and handle everything, so it doesn’t need to rely on your original depot to keep it running like a satellite does.

The downside is it’s resource-intensive because you need two (or three, or four) sets of drivers, managers, and everything else. This is why it makes the most sense when you’re scaling beyond two sites or when you’ve got enough consistent volume in a region to justify the investment.

Which should you choose?

For most courier companies, the satellite approach is a smart stepping stone. It keeps costs down and stops you from biting off more than you can chew. But if you’re running multiple sites and growing beyond two depots, full-service hubs are a better option.

Other multi-depot strategies to consider

While satellites and full-service depots are the main paths there are other models worth knowing about.

Depending on your contracts, geography, and fleet, these may give you more flexibility:

- Hub-and-spoke. One large central hub linked to a few smaller depots. Great for balancing high volume while covering lots of areas.

- Cross-dock. Parcels are moved from one vehicle to another without being stored long-term. Ideal for high-speed, time-sensitive operations.

- Micro-hubs. Small urban depots close to city centers, often used to cut congestion and make faster last-mile drops.

- Urban Consolidation Centers (UCCs). Shared facilities where multiple carriers consolidate their loads before delivering to busy urban areas.

- Pop-ups. Temporary depots (often in rented warehouses) to handle peak seasons like Black Friday or Christmas.

- PUDO points (Pick-Up, Drop-Off). Partner locations (shops, lockers) where customers collect or return parcels, which helps reduce failed deliveries.

- Virtual depots. Technology-led approach where drivers are assigned to geographic zones without a physical hub.

How to manage multiple depots

The biggest question that comes up when you move from one depot to multiple depots is: do you run everything centrally, or make each depot independent?

Mark’s view is clear:

“I would definitely think centrally wins there because it's more cost effective, it's easier to manage overall, you can always lean on software and communication apps that you might not necessarily need to use if you only had one depot. You can just keep core staff at each hub, and you can keep your high level staff then at one central depot."

Mark Whelan

Logistics Manager at Express Logistics

When we say “centralization” here, we don’t mean micromanaging every driver from HQ. Instead, it’s more about having total oversight of performance and comms and keeping decision-making under one roof. In the meantime, each depot handles its own day-to-day operations.

The tech glue

Managing one depot without tools or with limited automation is inefficient but possible, but as soon as you start adding more depots to the mix it becomes an almost impossible task. You absolutely need instant communication, says Mark.

“Without instant messaging and group chats, we'd have been in serious hot water. Often we’d get a message in the morning about a delivery that needs to be delivered at 9am, and if we don't get there by 9am these companies are ringing saying that they've suffered financial loss because of it.”

Mark Whelan

Logistics Manager at Express Logistics

Depot managers need to know as soon as a driver gets delayed so they can shuffle things around to avoid any knock-on effects.

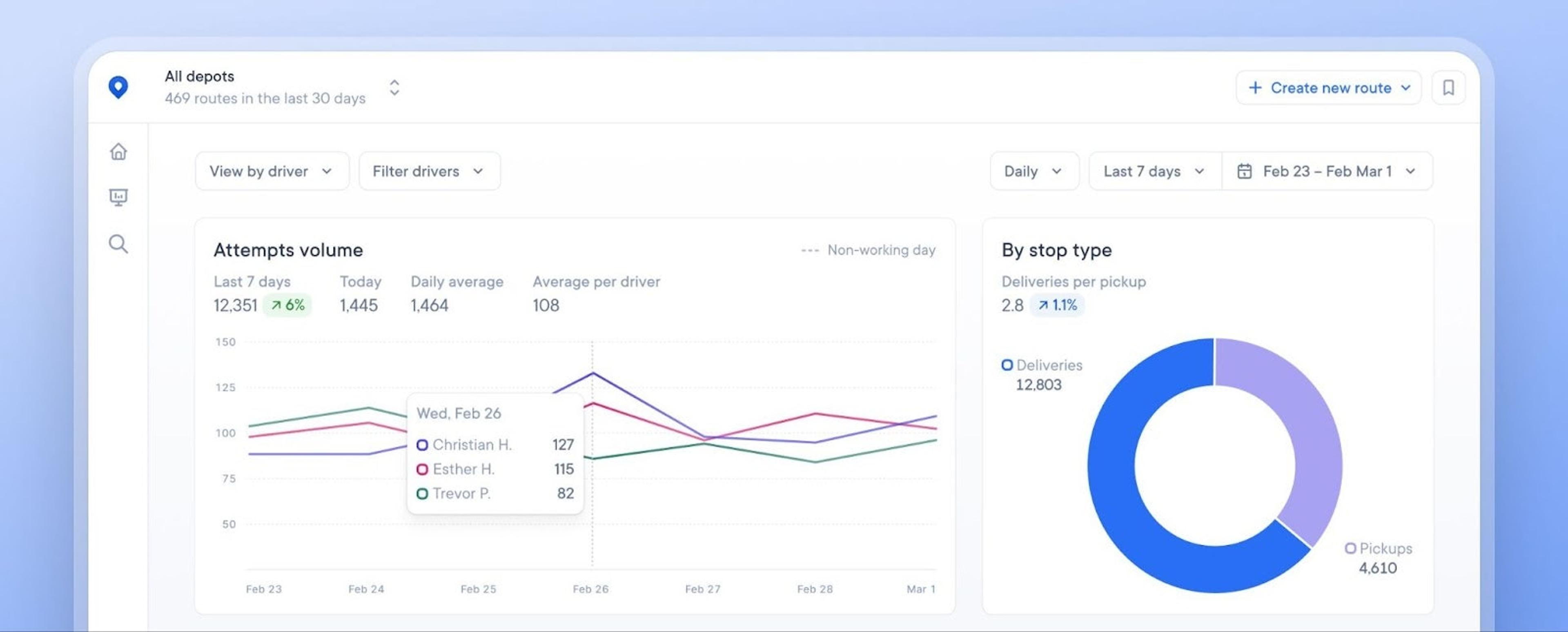

Beyond messaging, you need performance analysis software. As the saying goes, you can’t manage what you can’t measure.

Mark puts it simply:

“If you’re running two depots, you need to be able to track the data properly.”

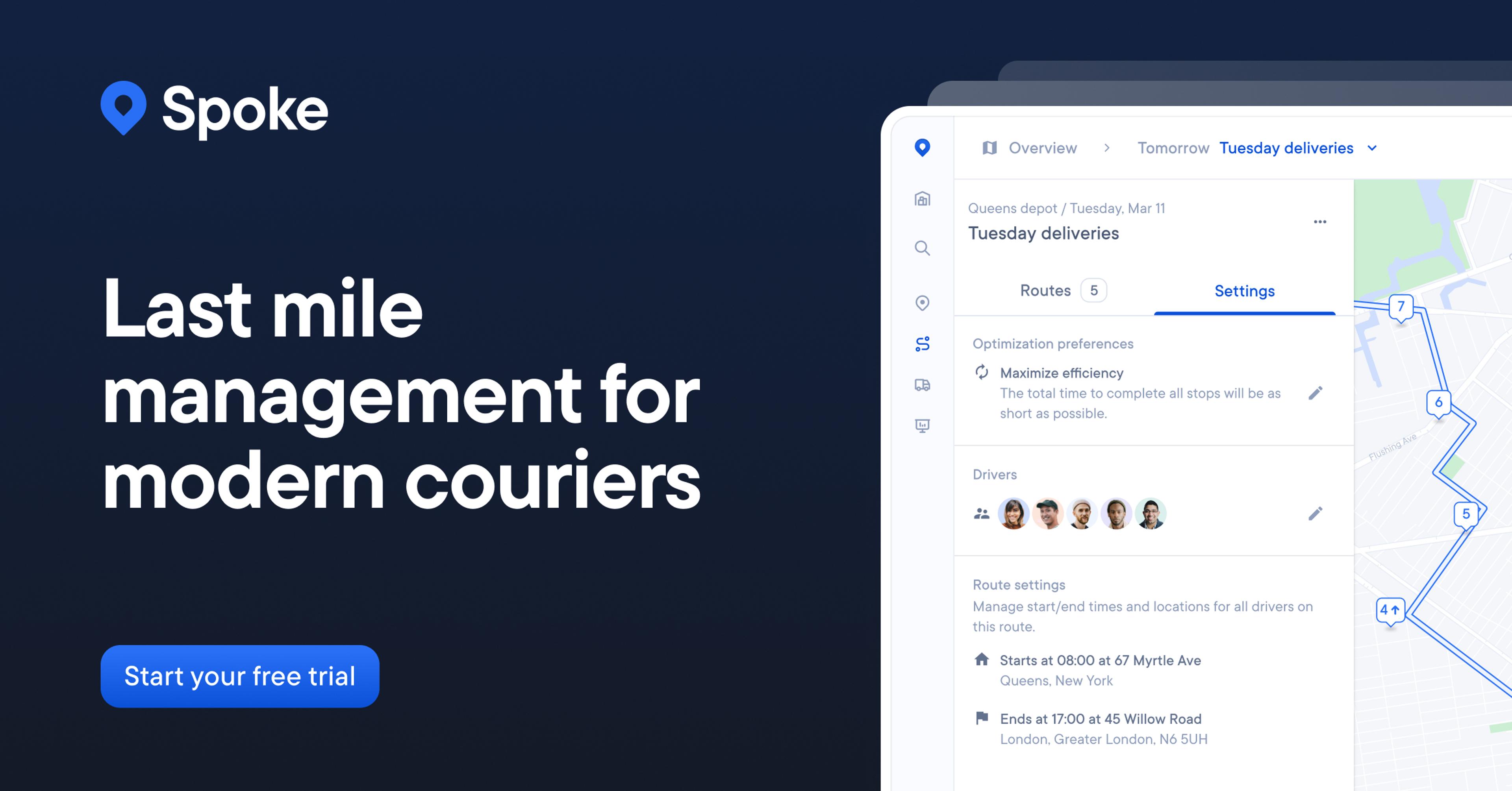

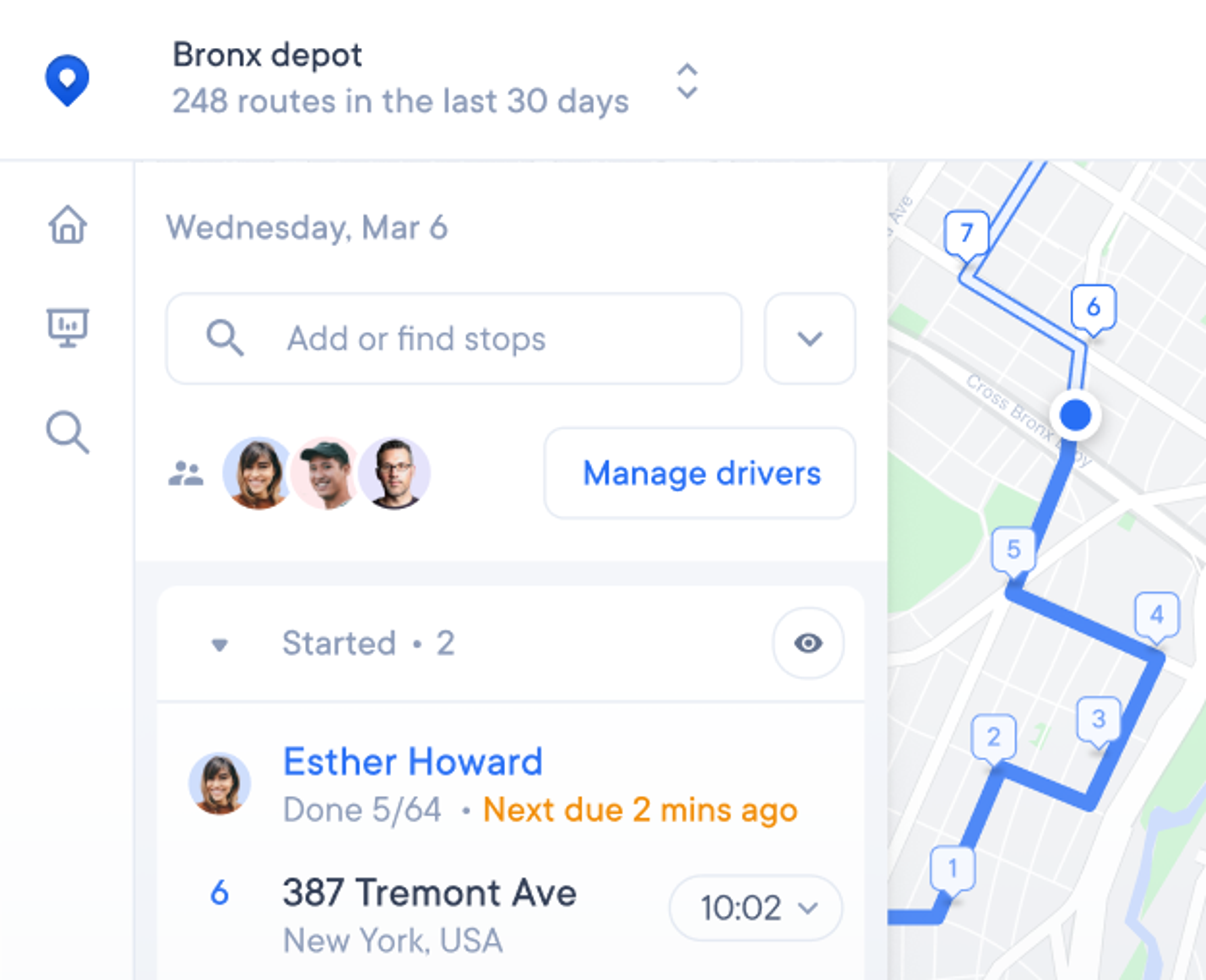

And as a Spoke Dispatch’ customer, Mark has a delivery analytics dashboard to help him identify areas of improvement in his last mile operation.

You can see:

- Driver performance reports so you know when a team is overloaded or underperforming.

- Cost per delivery trends to spot when routes are getting too long or fuel costs are spiking.

- Late and failed stops reports so you can drill down into why deliveries were missed and whether they’re clustered in areas that need their own hub.

- Planned vs. actual route comparisons to see when your schedules aren’t matching what’s really happening.

- Success rate tracking so you can monitor on-time delivery percentages over time.

- Depot/team/driver filters to compare performance across different locations or groups.

- Historical data and custom reports so you can look back over years of operations to spot growth patterns and predict when your depot will hit its limit.

People still matter

That said, tech only works if your people use it well. Trusted managers are the backbone of a successful multi-depot setup, and you need people who can keep those standards high even if they’re not actually on-site.

Invest in training around communication and using the software properly to make it easier for staff to grow with your operations.

The balancing act

When you drill down into it, managing multiple depots is really just about balance. You’re balancing oversight with local autonomy, you’re balancing costs with a high quality of service, and you’re balancing powerful technology with traditional human judgement (often from people who’ve been in the industry for many years).

The courier companies that do well with multiple depots are the ones that can manage this fine balancing act that keeps all hubs in sync and everyone on the same page.

The biggest pitfalls of multi-depot expansion

Adding more depots to your business is a high-stakes move. You’re not just copy-pasting your existing ops.

The biggest mistake courier companies make is handing the keys to subcontractors. Mark has seen this play out more than once (spoiler: it rarely ends well).

“We've seen first hand companies using subcontractors to run whole depots and service their geographical areas,” he says. “And it ends up then with poor service to customers and high complaints, and the subcontractors say they can't maintain the depot, they can’t pay the utility bills and the driver wages with such tight margins, and it just ends up in failure.”

On paper, outsourcing might look like a quick and easy way to scale, but in reality you lose control over quality and it’s your reputation (and revenue) that takes the hit.

Another common pitfall is skimping on good tech. Without strong systems for route planning, tracking last-mile performance, and communicating between drivers and depots, you’ll struggle to keep everything in sync. This often means problems don’t get spotted early enough and fixing them after they snowball is far more expensive than investing in the right tech from the start.

Finally, expansion often stretches your leadership team way too thin. You need people both on- and off-site who value high standards and go out of their way to uphold them. It ultimately boils down to the fact that growth does not equal more buildings. Instead, it’s about running those new facilities well, and you need trusted, experienced staff to do that.

The lesson here is simple: don’t cut corners. Take your time and invest in building the right systems and hiring the right people.

The future of multi-depot courier networks

So where’s all this heading? From what we’ve seen working with hundreds of courier companies and speaking to knowledgeable industry folk, the future of courier networks is looking smaller, smarter, and more localized.

Mark thinks this is partly because electric vehicles will shape the next wave of growth.

“I believe smaller depots will be the way to go, bringing the goods closer to the customer for quicker and more reliable service. And the reason for this is electric vehicles. We see some of our competitors now using electric vehicles, but some of our routes are up to 400 kilometers, so electric vans won't cover that sort of range. Having smaller depots where you can bring the goods closer to the customer would improve that.”

Mark Whelan

Logistics Manager at Express Logistics

That means instead of one giant facility feeding huge areas, we’ll see more mini-depots dotted closer to where customers actually live. This kind of setup will reduce “range anxiety” for EVs and makes it easier to fulfill same-day and next-day orders.

At the same time, tech will be the glue that holds it all together. When you’ve got a smattering of small depots instead of one central hub, you need software to link them all together while still letting each depot have some semblance of independence.

“And I’d also say leaning on last mile management software that improves routing and control for ops employees. It's a lot easier to split up consignments, move them around and run multiple depots centrally with it in place.”

Mark Whelan

Logistics Manager at Express Logistics

That’s the big shift: courier networks will rely less on brute force (a.k.a. big fleets, long routes, giant hubs, etc.) and more on intelligent coordination.

The companies that get ahead of this new growth wave will be rewarded with lower costs and greener operations, both of which will impact the end customer. The ones that cling to old models might just find themselves outpaced (literally) by competitors who are willing to experiment and evolve.

Why growth is more than just “another” depot

Having just one depot has its perks. It’s cheaper to control and easier to keep an eye on, which keeps you lean and means you can react quickly when problems pop up. For a lot of courier companies, that single-hub model can take them surprisingly far.

But there’s a ceiling. Once drivers are racking up hours before their first stop or contracts are slipping through your fingers because you’re out of range, it might be time to think bigger.

Multi-depot operations are the key to growth and serving new markets, but they bring their own set of challenges. More sites mean more people and more moving parts, which requires strong systems and trusted managers.

To do it right, don’t rush. Weigh the costs, plan carefully, and lean on both data and industry experience to make the leap when the time is right.

“Talk to other operators that have been in that position and learn from their experience,” says Mark. “Because experience, it can't be bought, it can only be shared.”