Last Mile Delivery: what it is and how to get it right in 2025

Last mile logistics account for over half of your company's total shipping and fulfillment costs.

Soaring customer expectations for speed and visibility are reshaping the entire logistics industry.

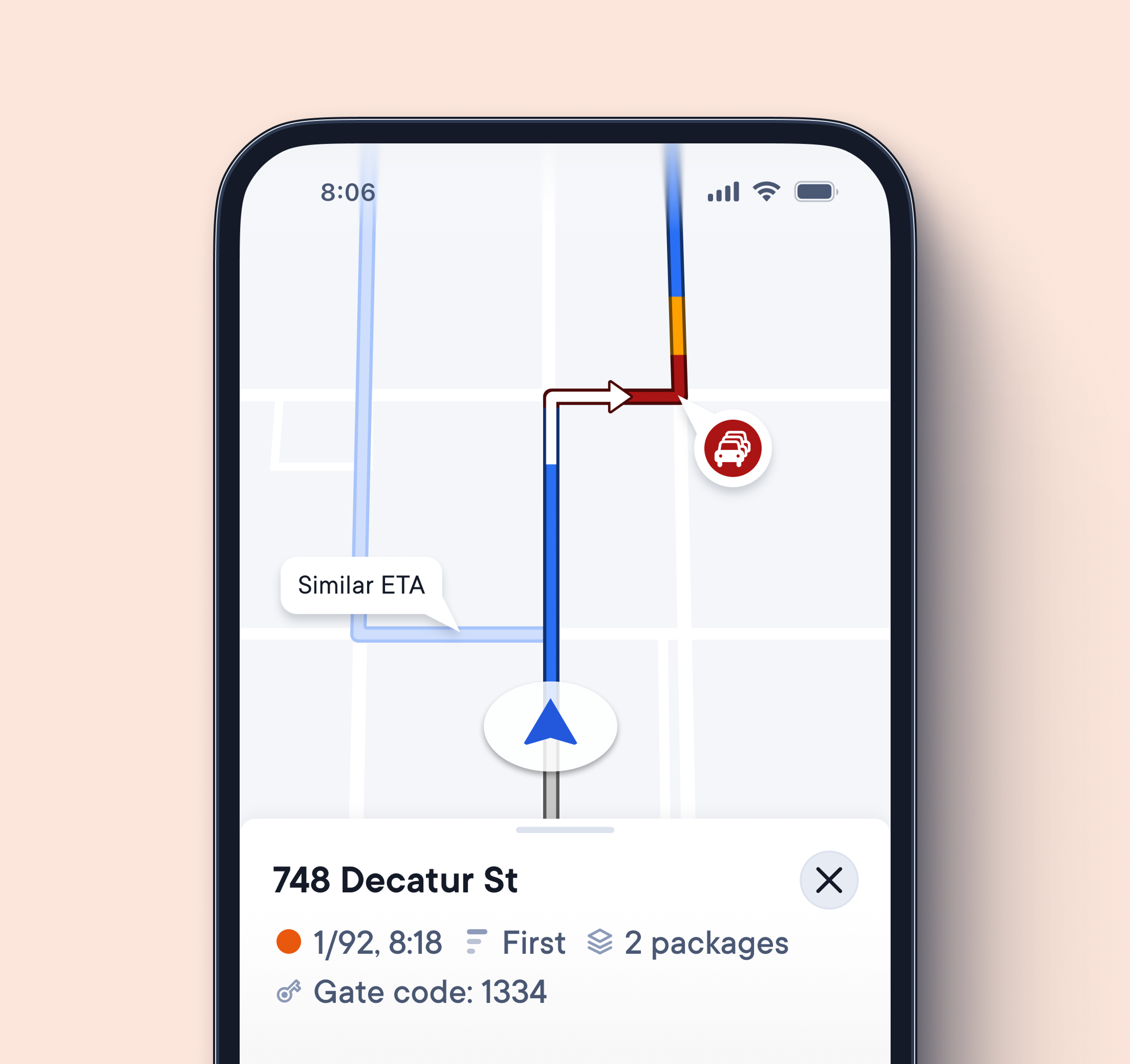

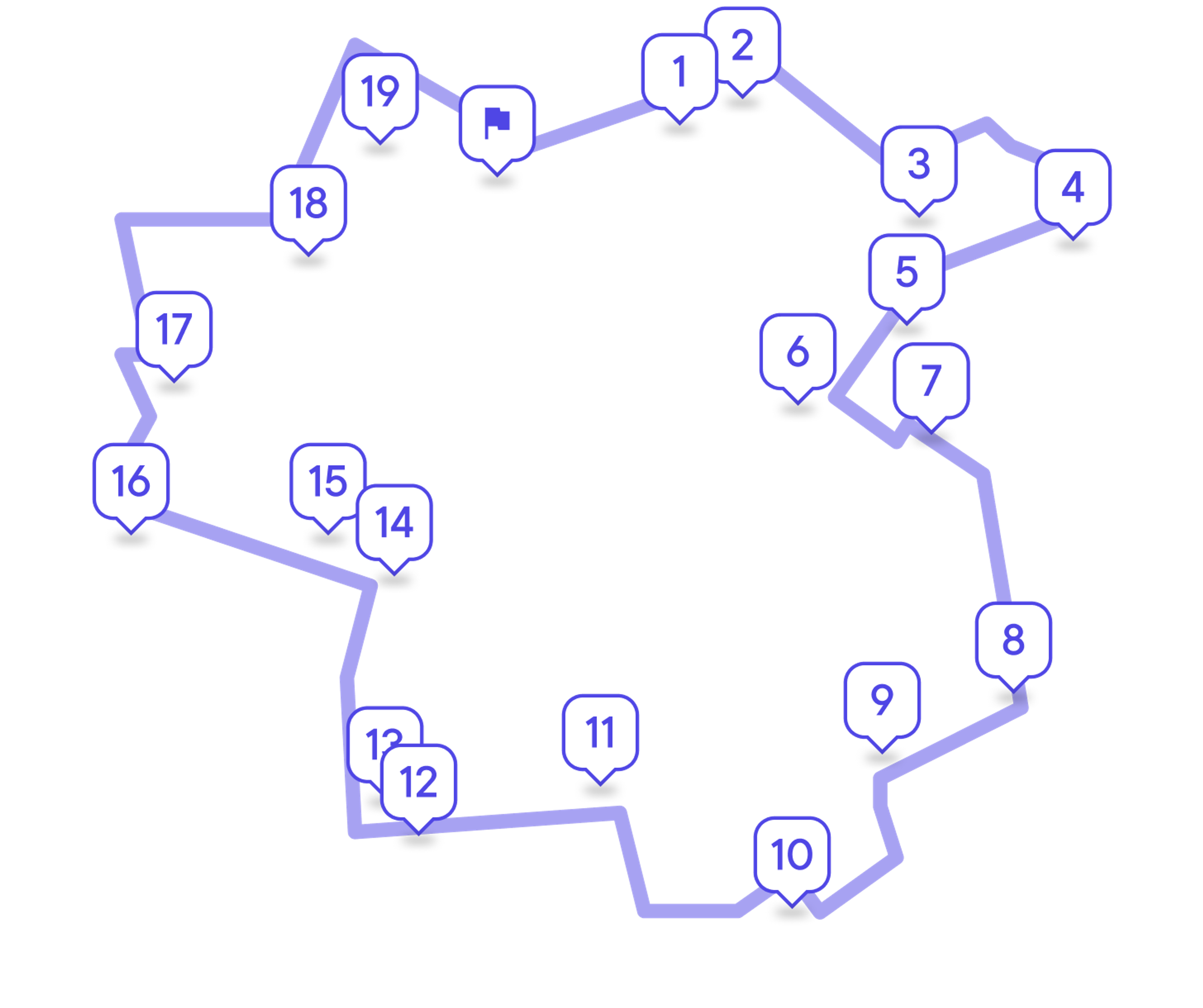

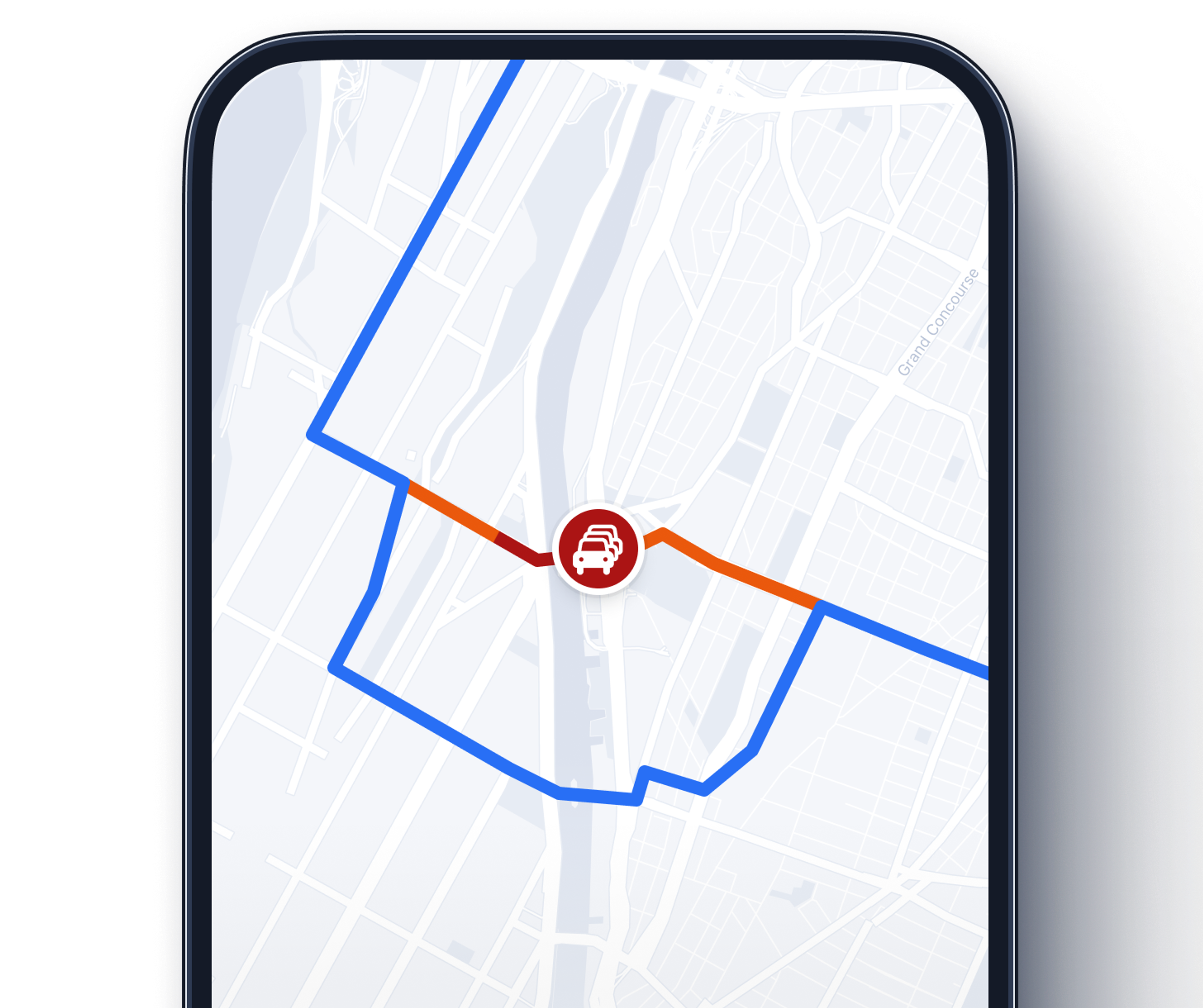

Route optimization software makes delivery faster and smoother by planning the most efficient driver paths.

Smart delivery teams turn performance analytics into major operational improvements and cost savings

Introduction

Last mile delivery is the part of the supply chain that gets a package from a local hub to the customer’s door. On paper, that sounds simple. In practice, it’s usually the hardest and most expensive stage of the whole process.

The last mile differs from the other stages significantly. First and mid-mile moves are about shifting bulk shipments from one place to another. The last mile on the other hand can often splinter into thousands of stops, all with different locations, unexpected changes, traffic, weather, and customers who each have their own requirements.

And customer expectations are becoming increasingly difficult to live up to. People want speed, but they also want updates, flexibility, and a clear picture of where their delivery is. If they can track all the different stages of a pizza order, they expect the same level of detail for everything else.

This guide will walk through what last mile delivery actually is, how it works, and why its success matters so much for delivery teams.

Skip ahead to a section that interests you:

01

What is last mile delivery?

02

Types of last mile delivery

03

Last mile delivery service levels

04

What last mile delivery looks like in action

05

What is the last mile delivery problem?

06

Breaking down the challenges of last mile delivery

07

How technology is helping couriers solve last mile challenges

08

Example of how last mile management software is used in last mile delivery

09

The consequences of poor last mile delivery

10

Why last mile delivery is so important to get right

What is last mile delivery?

As mentioned, last mile delivery is the final stage of the logistics process, where a package moves from a local distribution hub to its final destination which is typically a customer’s home or business.

But to define it further, it makes sense to briefly explore the other stages of the logistics supply chain.

Step 1

First mile delivery

The transportation of goods from the point of production (e.g., manufacturers, farms, suppliers) to distribution centers, fulfillment hubs, or retailers. This often involves freight carriers, shipping containers, and large-scale transportation. For example, in eCommerce, first-mile delivery includes moving goods from a supplier's factory to an Amazon fulfillment center.

Step 2

Mid mile delivery (or middle mile)

The movement of goods between warehouses, regional distribution centers, or local fulfillment hubs. This stage is focused on bulk transport and sorting before the last mile begins. It often involves regional trucking. For example, Walmart uses middle-mile logistics to transfer products from larger distribution centers to neighborhood stores.

Step 3

Last mile delivery (or final mile)

Here the goods are split into many routes, with the destinations likely being to customers’ homes or businesses. This stage relies on box trucks, delivery vans, cars, mopeds, and even bikes for urban areas. It’s also the most complex and costly due to customer expectations, time-sensitive delivery windows and the chance of failed delivery.

Types of last mile delivery

Here are some common types of last mile delivery.

Medical and pharma

This delivery type involves the transportation of prescription medications, lab samples, and emergency medical supplies. Many of these require specific handling protocols and certifications, temperature-sensitive vehicles or packaging, and mandatory proof of delivery.

B2B last mile logistics

As mentioned, not all last mile deliveries go to people’s houses. Businesses will also rely on last mile networks for office supplies, industrial equipment, and bulk inventory restocking. These often involve scheduled deliveries, special handling, or recurring routes.

White-glove

This is simply a premium service for high-value, fragile, or bulky items that need extra care. The delivery driver might enter the home to build the product, say a bed or sofa for example. Assembly, installation or lifting to higher floors is common with this type.

Food and grocery

The biggest factors are time and/or environment. If you’re delivering frozen goods you’ll need to ensure vehicles have temperature control and fresh food will need to be delivered fast.

Express

Express delivery is all speed. Handling urgent shipments like medical supplies, legal documents, or same-day ecommerce orders and completing delivery on the double.

Gig economy

This delivery type involves independent contractors using their own vehicles to complete last mile deliveries. This is usually solo drivers using Uber Eats, Deliveroo, JustEat, etc.

Last mile delivery service levels

As well as different types of last mile delivery, there are also different last mile delivery service levels that can be applied across these types.

Ultra-fast fulfillment, often used for food, groceries, and urgent ecommerce orders, where speed is the key factor for customer satisfaction and loyalty.

The standard for premium ecommerce delivery (Amazon Prime, Walmart+), striking a popular balance between rapid fulfillment speed, reliability, and affordability.

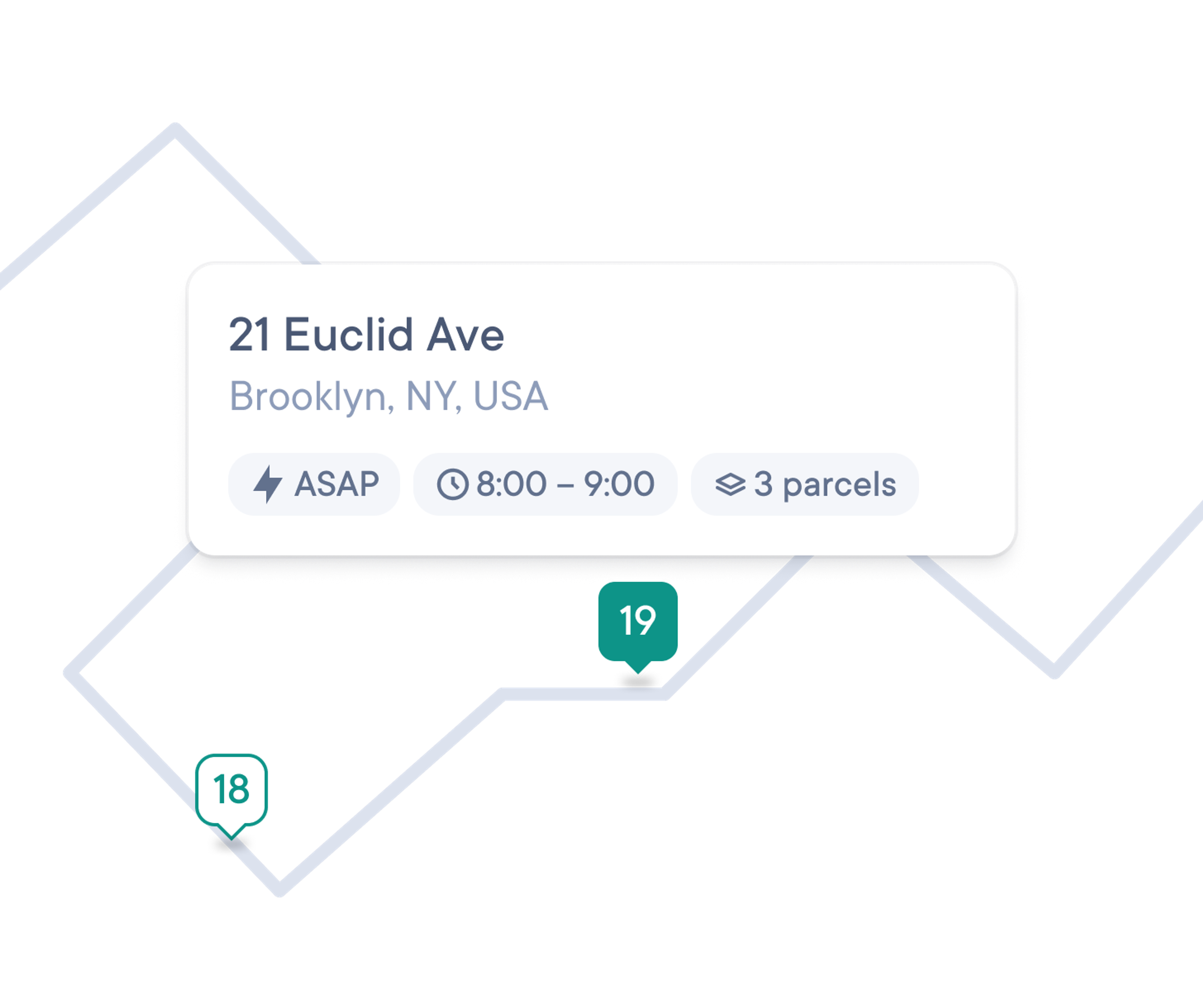

Used for larger items (furniture, appliances), groceries, and B2B logistics, allowing customers to book a specific time slot for convenient and predictable delivery.

App-based and gig-economy-driven (Uber Eats, DoorDash, Instacart, etc), usually for food deliveries, allowing users to place an order and have it delivered almost immediately.

Offering multiple delivery options is great for customers but it also means more complexity behind the scenes, so let’s break down how last mile delivery actually plays out in the real world.

What last mile delivery looks like in action

Last mile delivery is a multi-step process.

The 6 key stages of last mile delivery

The last mile provider can be the in-house delivery fleet if the business is using their own drivers, a third-party logistics company (3PL - who usually manage the mid-mile too), a courier company, a delivery service partner (DSP) that the courier company subcontracts to, or a solo courier.

Handoff from fulfillment

Once a package leaves the warehouse or retail location and is in the possession of the last mile provider it’s officially in the final mile. The dispatcher will likely receive the list of delivery stops just before the physical packages arrive at the depot.

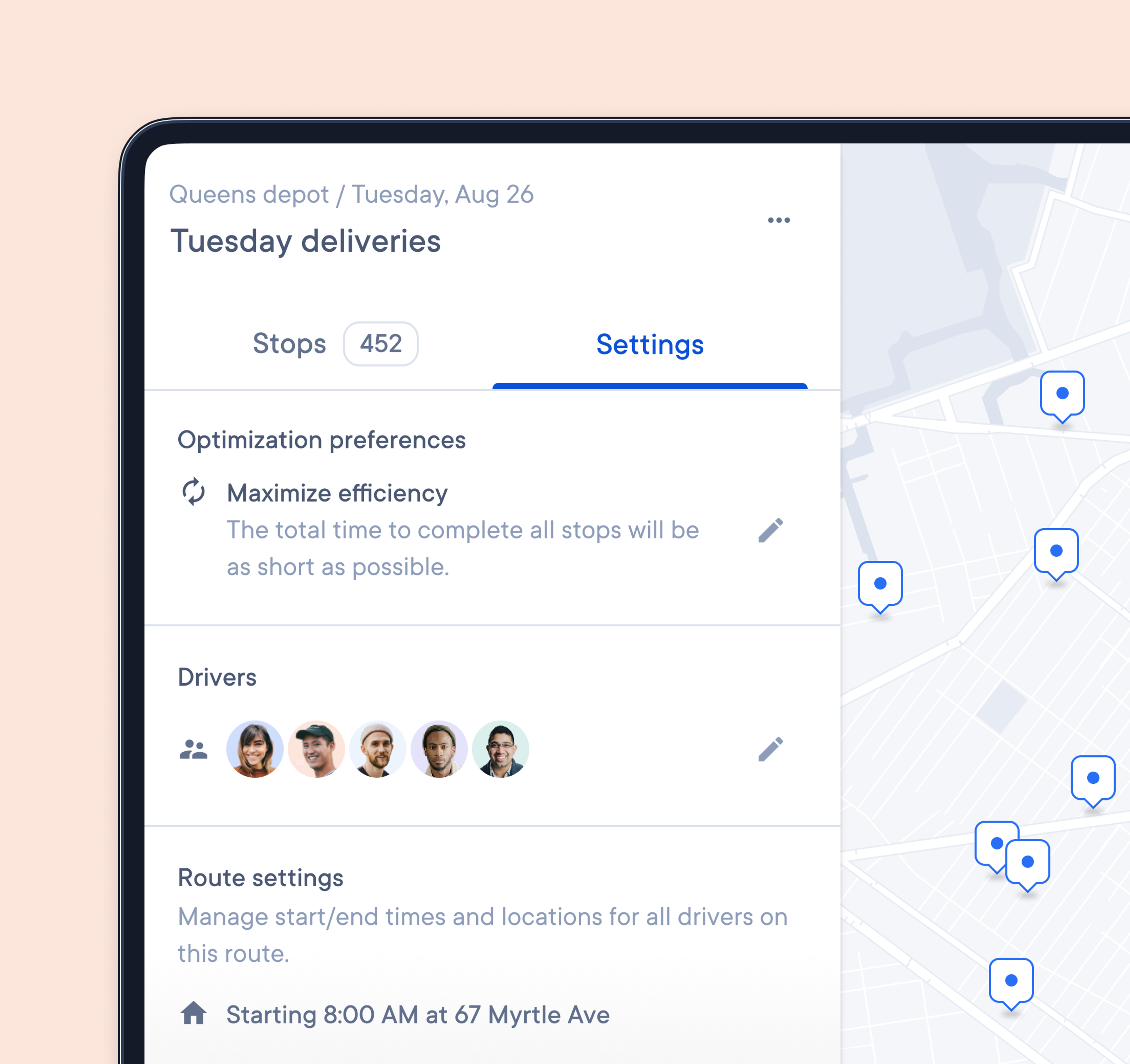

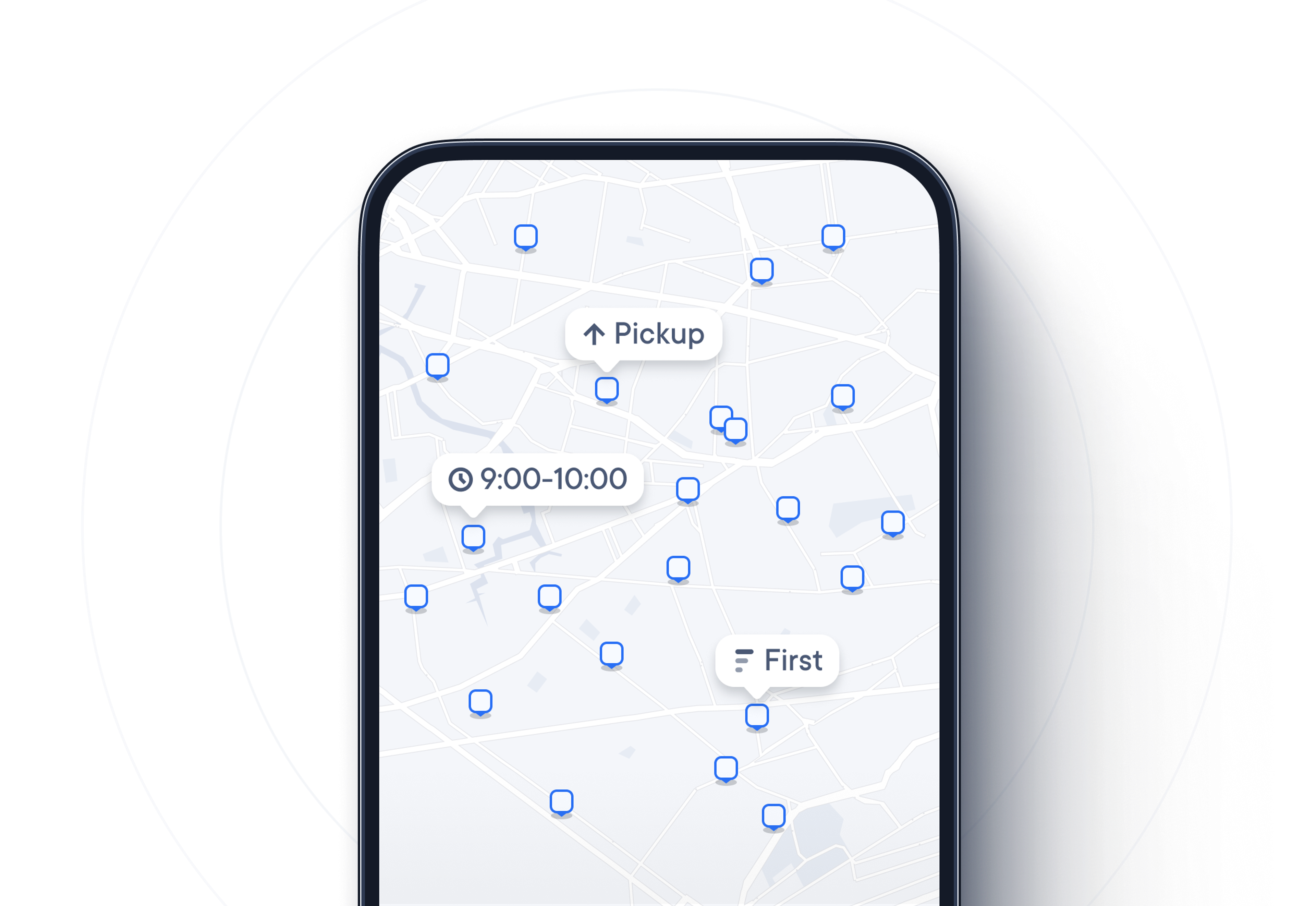

Route planning

Before the packages then hit the road, dispatchers assign deliveries and plan routes based on driver availability, location, delivery time windows, and vehicle types. Some still do this manually, but many rely on route optimization software to create efficient routes and save the most money on fuel and driver costs and vehicle wear and tear.

Loading & dispatch

At the depot or distribution hub, packages are sorted and loaded into vehicles and they’re typically grouped by delivery zone, priority, or delivery type. This is also when any special handling (e.g. temperature control or fragile goods) is factored in.

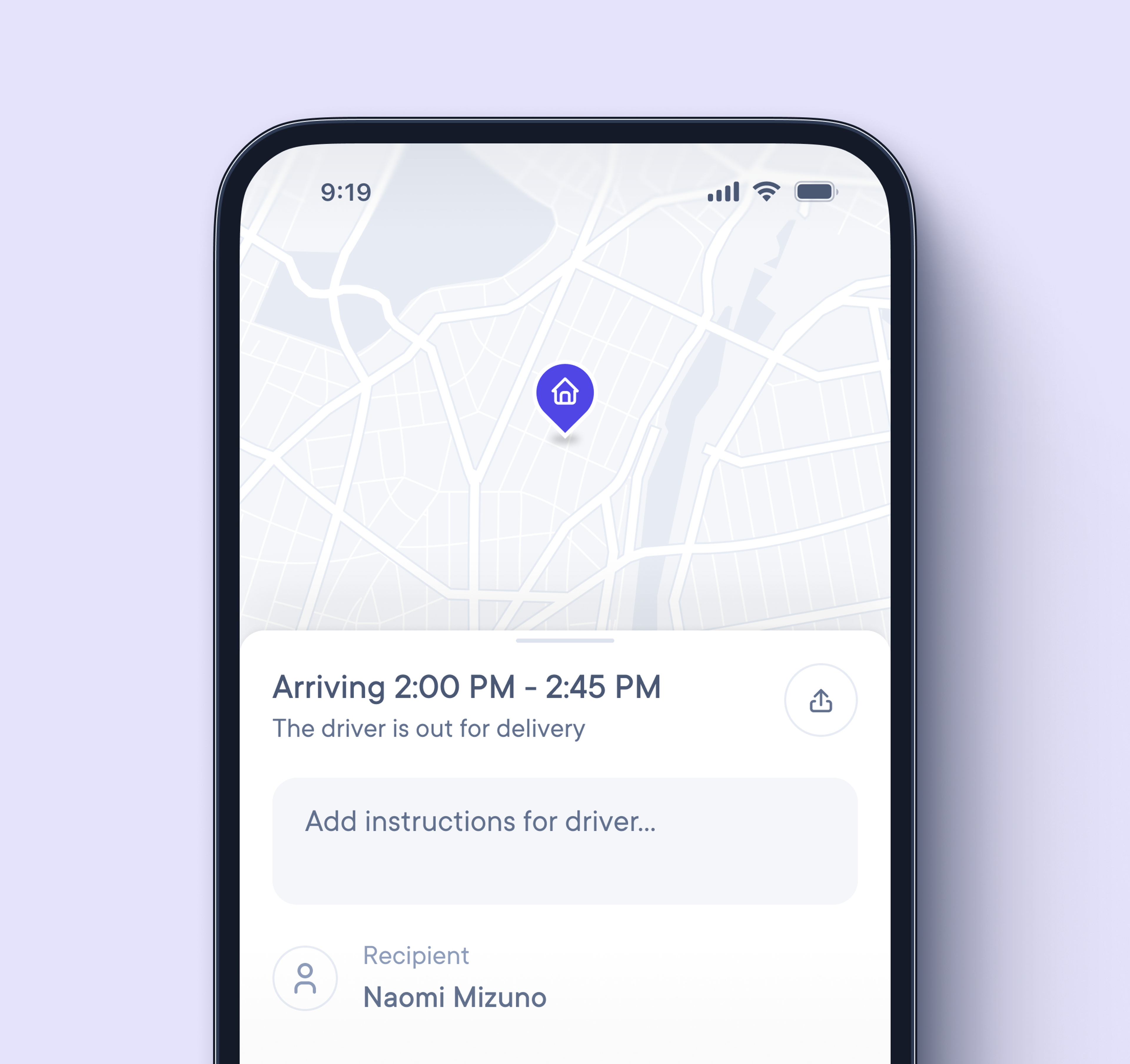

Tracking & notifications

Once the driver is on the road the delivery is live. If the company has route optimization software, dispatchers will watch the day’s deliveries play out in real-time from their laptops. Real-time GPS tracking gives them full visibility into the progress of each route, while customers waiting on their packages will receive updates via SMS, email or an app.

Delivery attempt

Then there’s the moment of truth. The actual delivery attempt. Not every delivery goes smoothly, and challenges like incorrect addresses, gated buildings, or customers not being home can regularly cause delays or re-attempts. Companies that offer flexible options like safe-place delivery, fixed or dynamic delivery windows, or rescheduling tend to have the lowest failed delivery rate %.

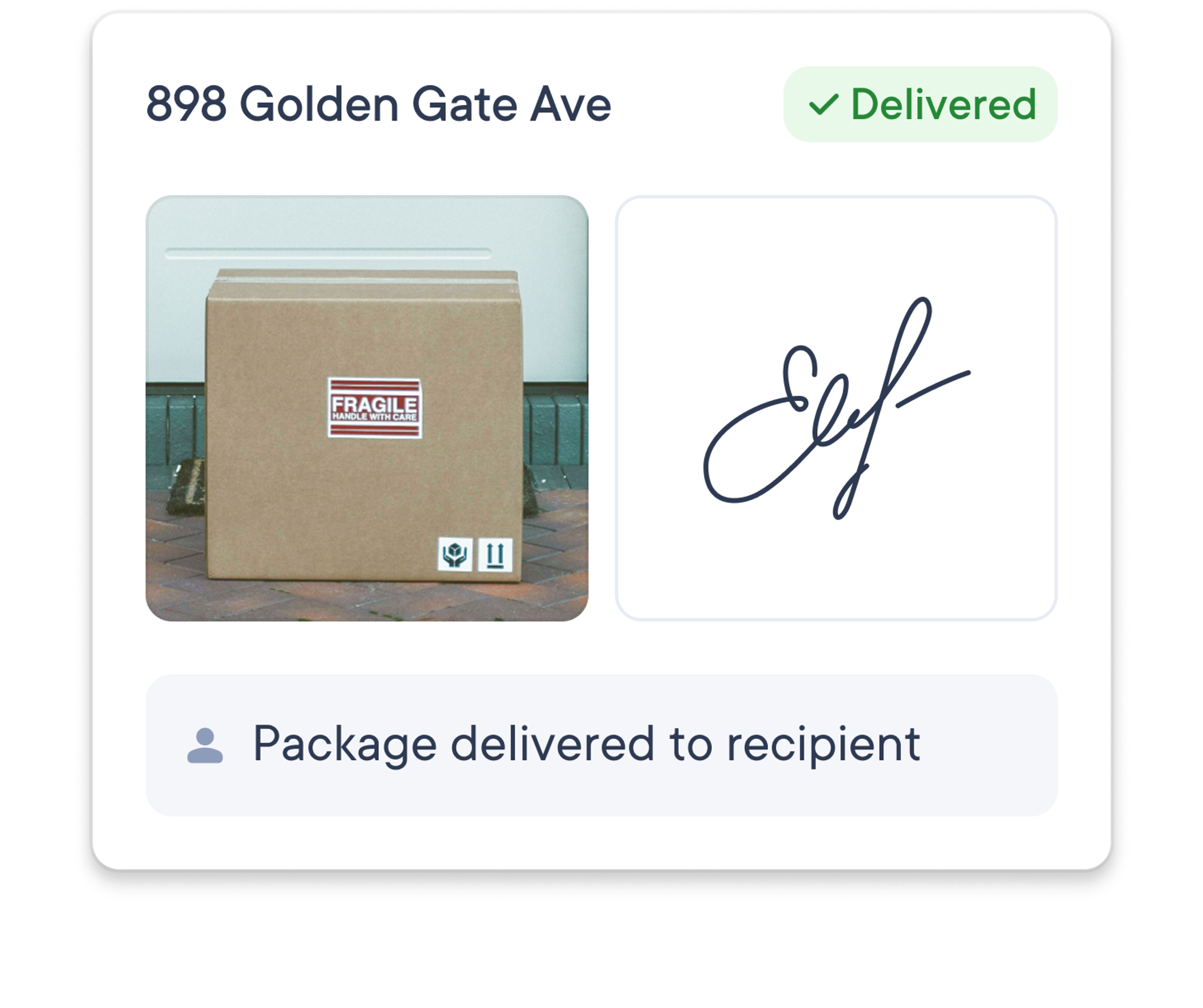

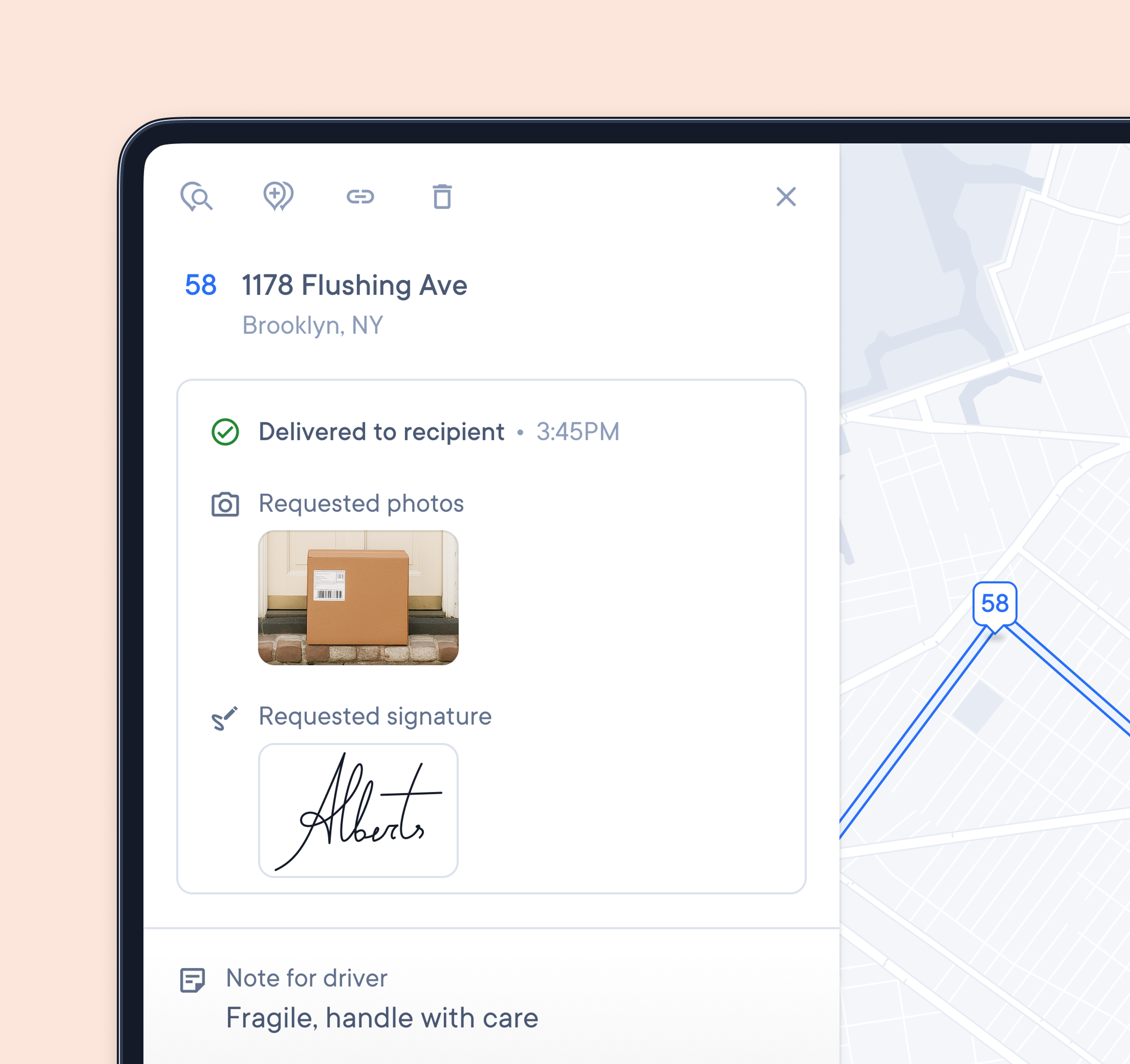

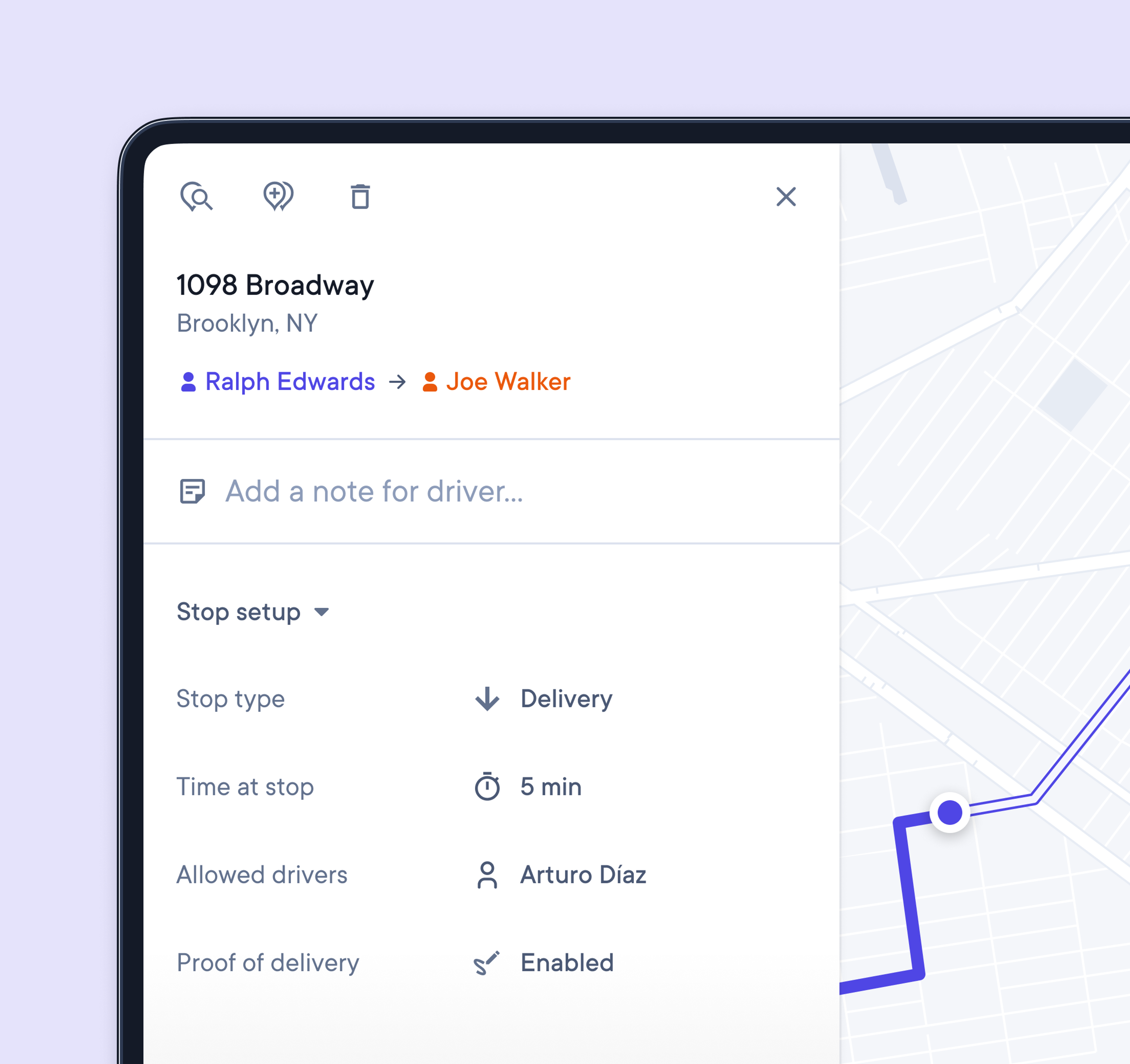

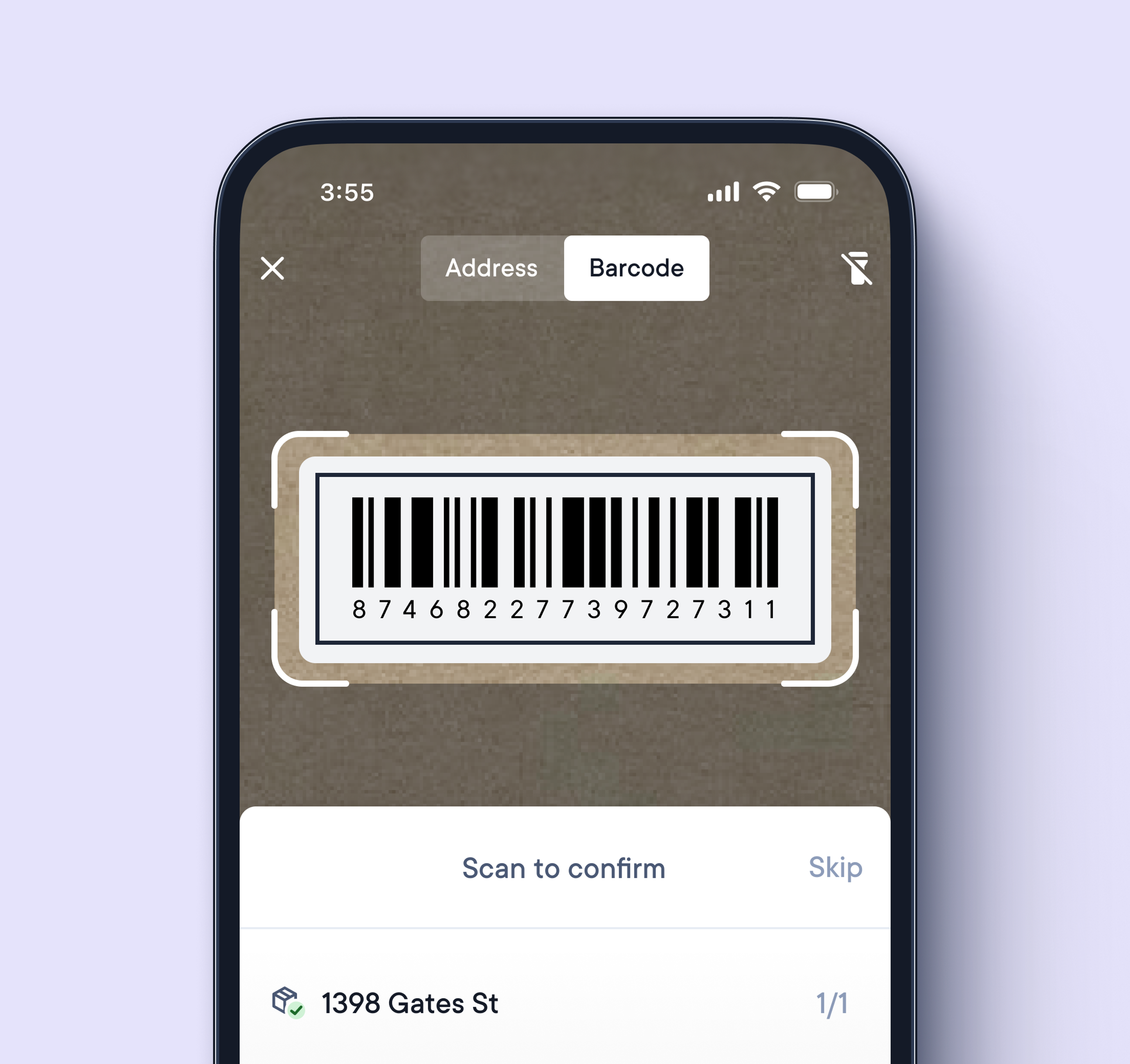

Proof of delivery (POD)

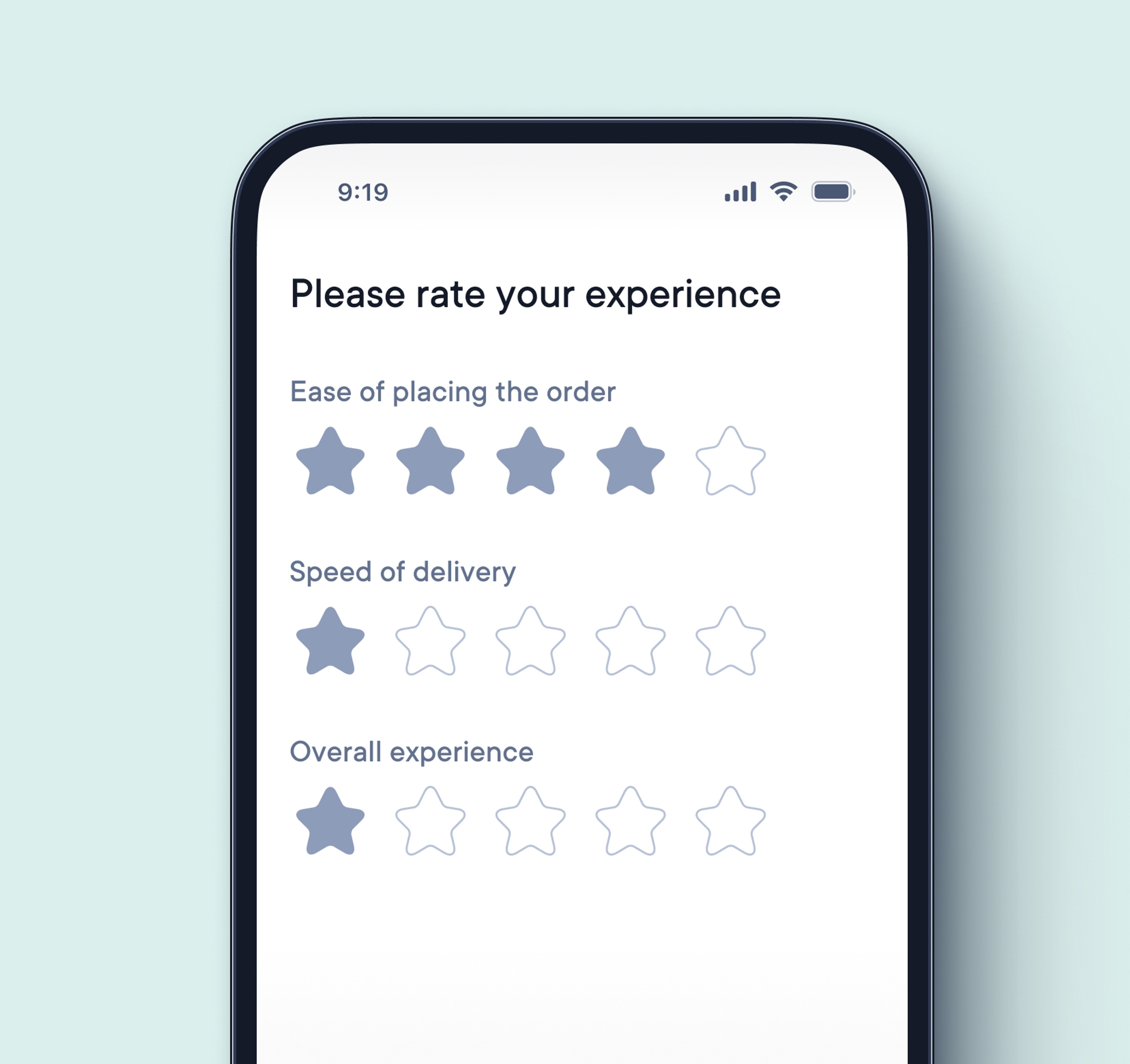

Once the package is delivered, POD is captured in the form of a photo, e-signature, or GPS timestamp. It’s common for courier teams to follow up with quick surveys or feedback requests to improve future experiences and to report on their performance.

Of course, behind all these last mile delivery stages are the people actually making it happen. Once a package is on the road, two roles become especially important, the dispatchers and drivers.

Let’s take a look at how their days unfold.

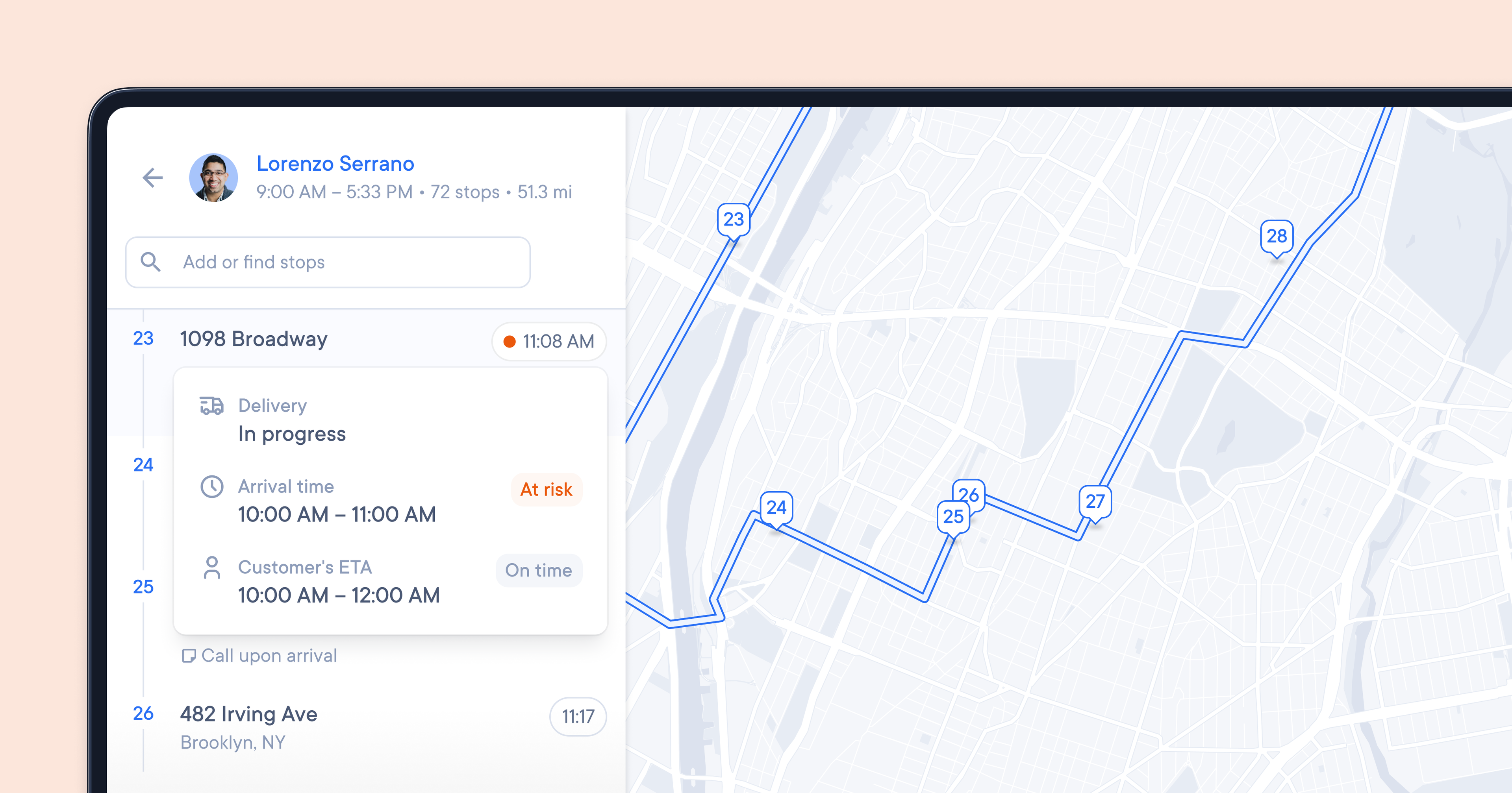

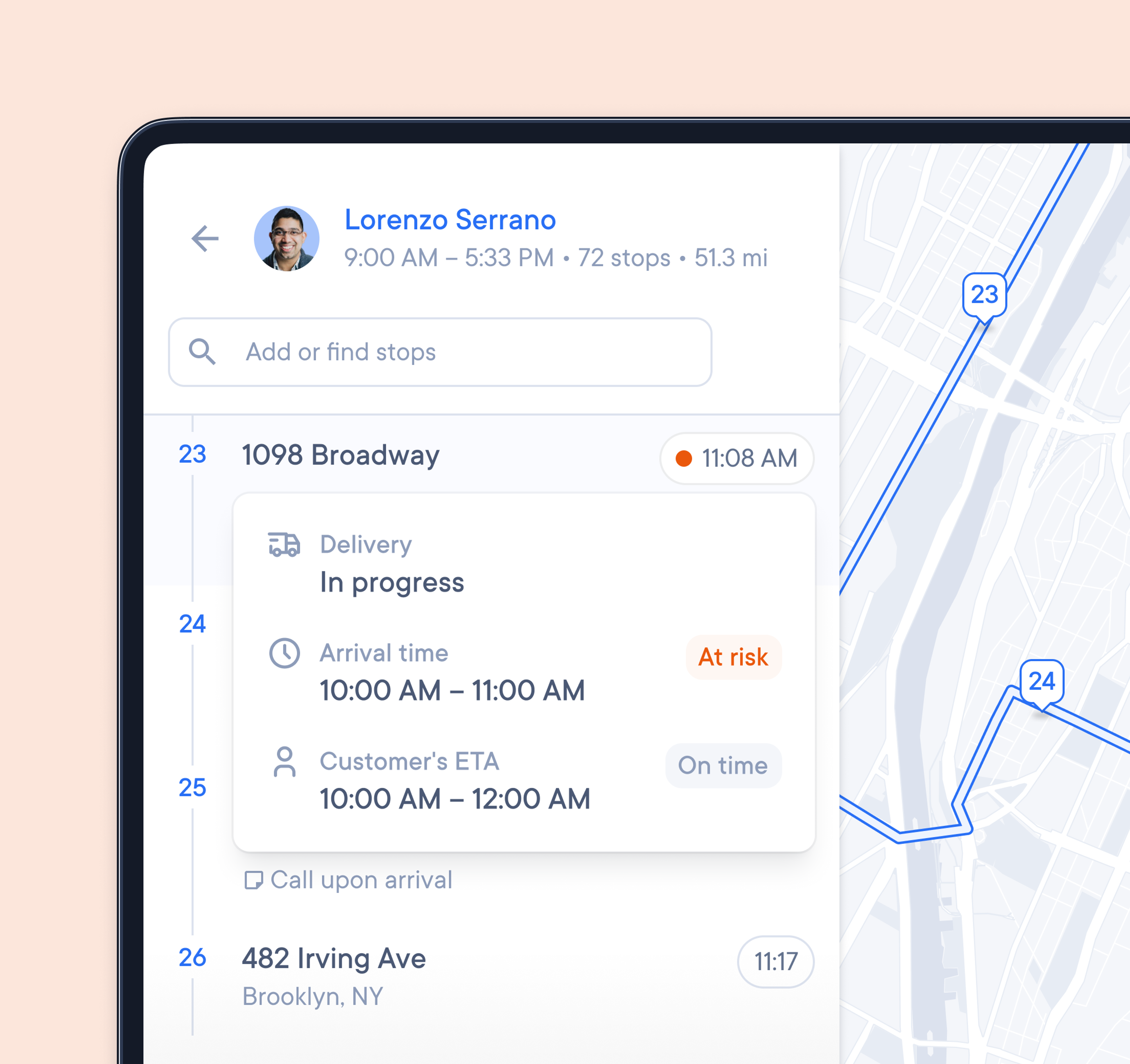

A day in the life: dispatchers

Dispatchers plan the routes and then oversee the operation once the drivers have left the depot or distribution hub. They run the command centre, making sure deliveries are on track, problems are solved/removed for their drivers, and recipients get their packages without issue. Here’s what their day might look like.

Morning planning and route optimization

Planning the day ahead

Their day begins by analysing package volume, driver availability and any specific requests like delivery windows and stop priority.

Create optimized routes

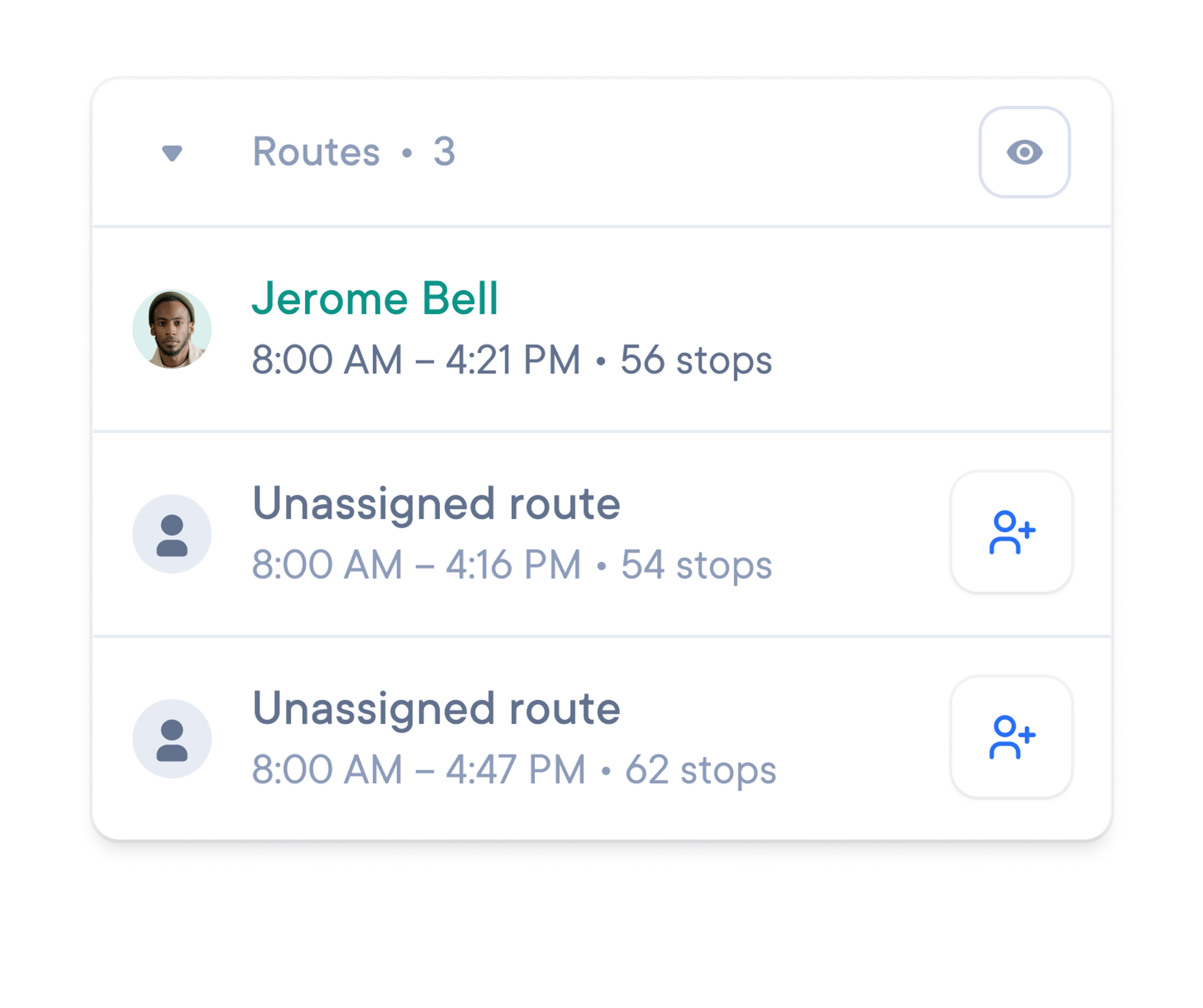

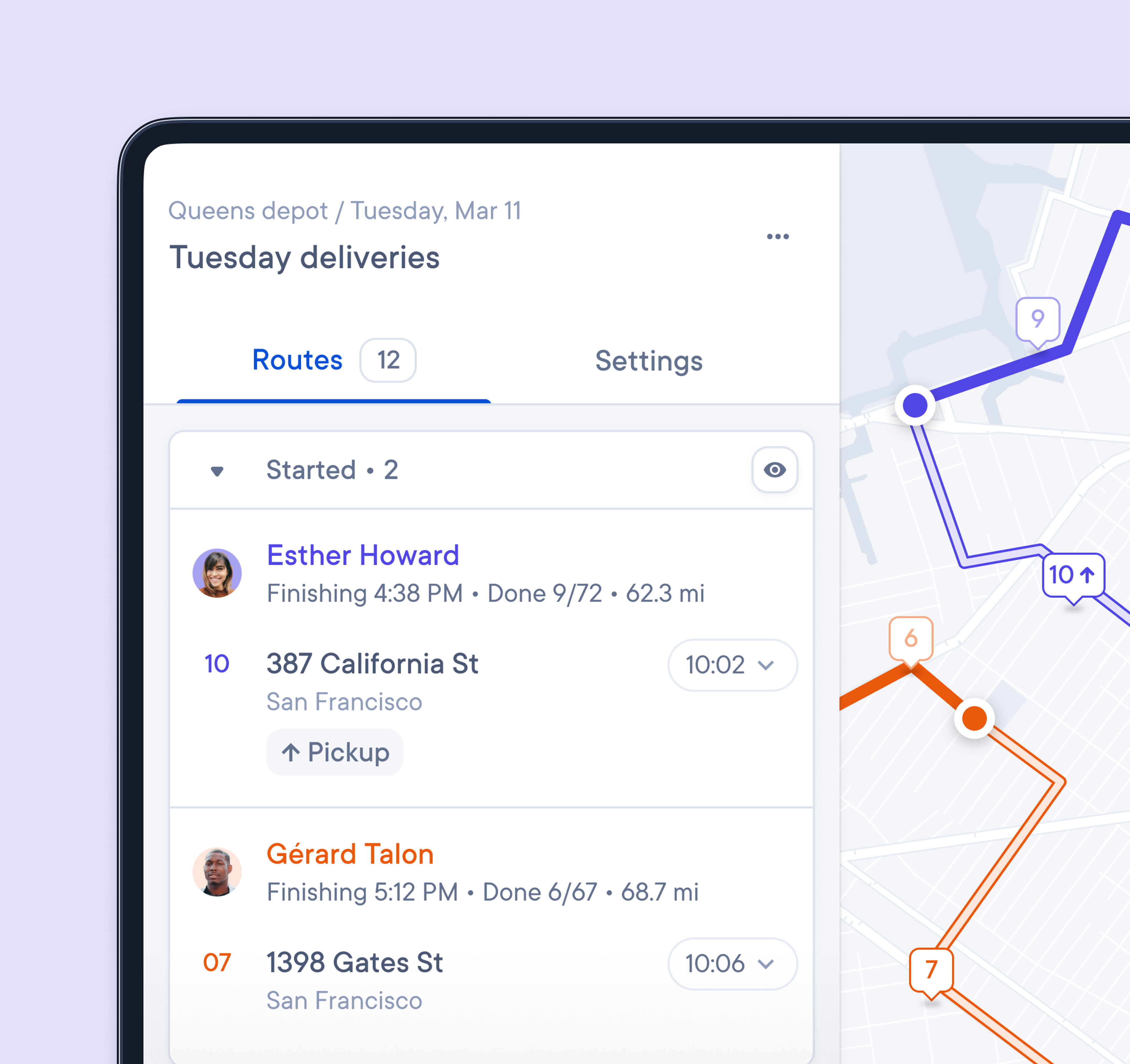

Then, if they’re using route optimization software, they’ll upload their delivery stops for the day via spreadsheet or API integration, and create the most efficient routes for the day at the click of a button.

Assigning routes to drivers

Once the routes are created, dispatchers will assign them to drivers.

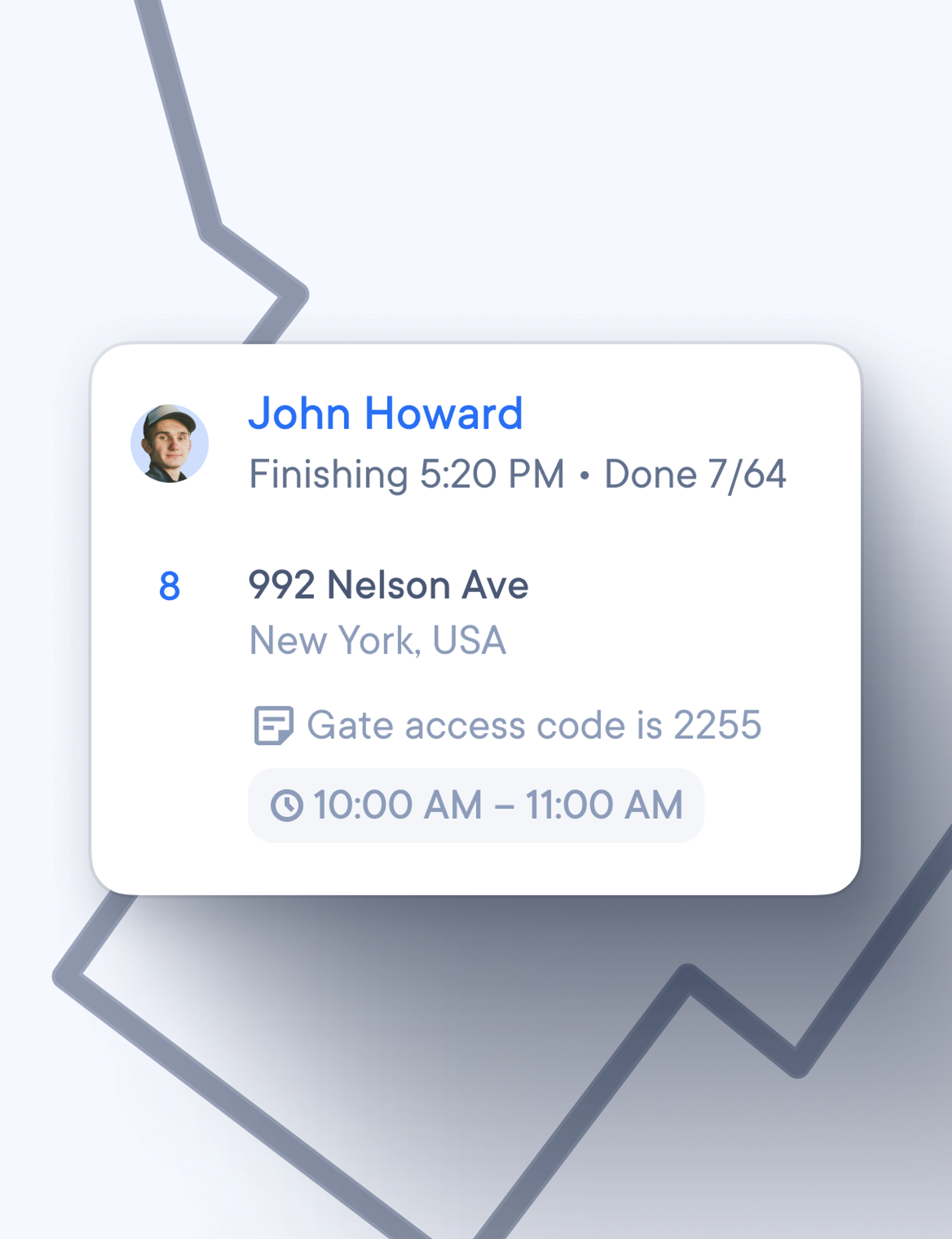

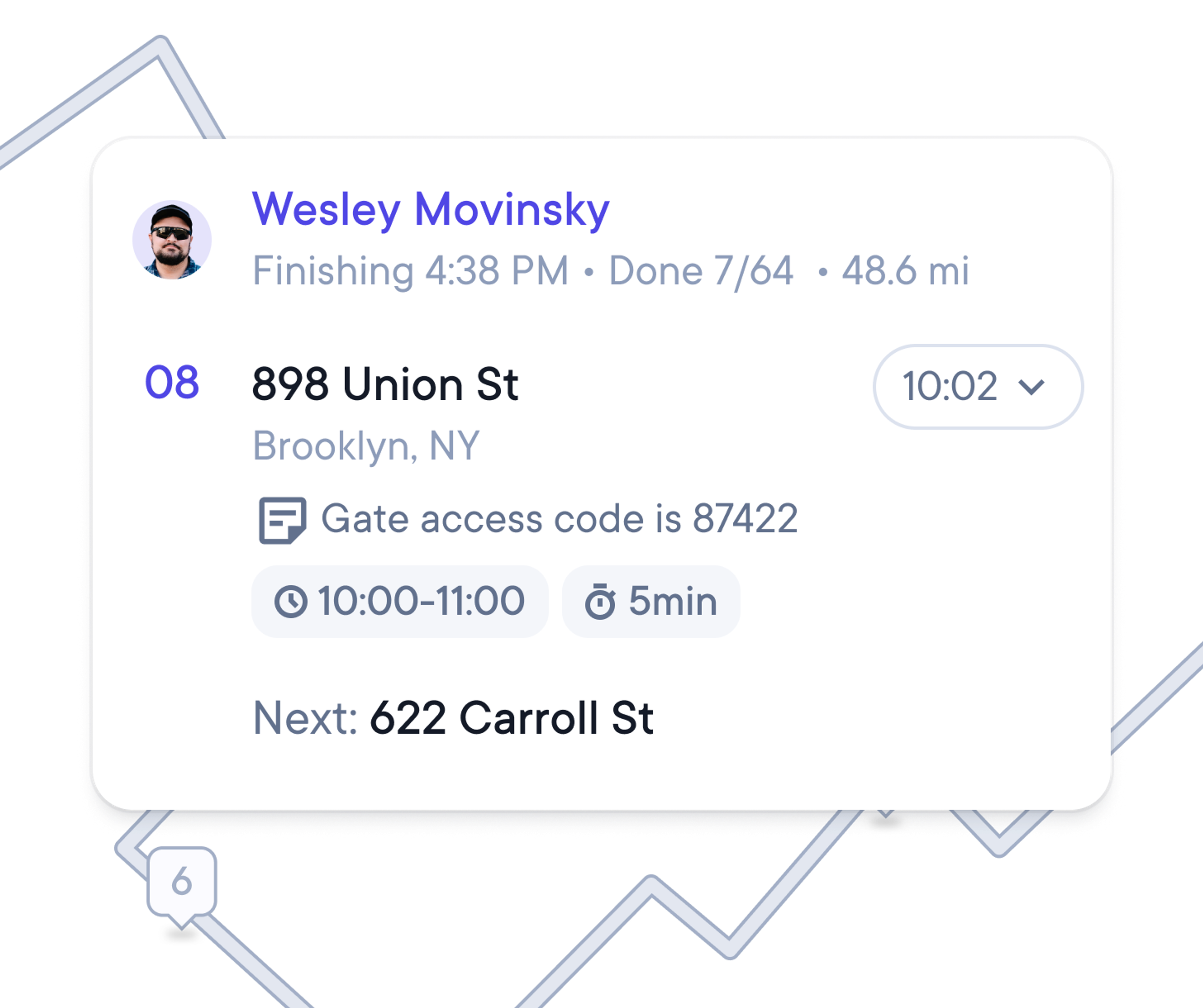

How the dispatcher assigns stops and route

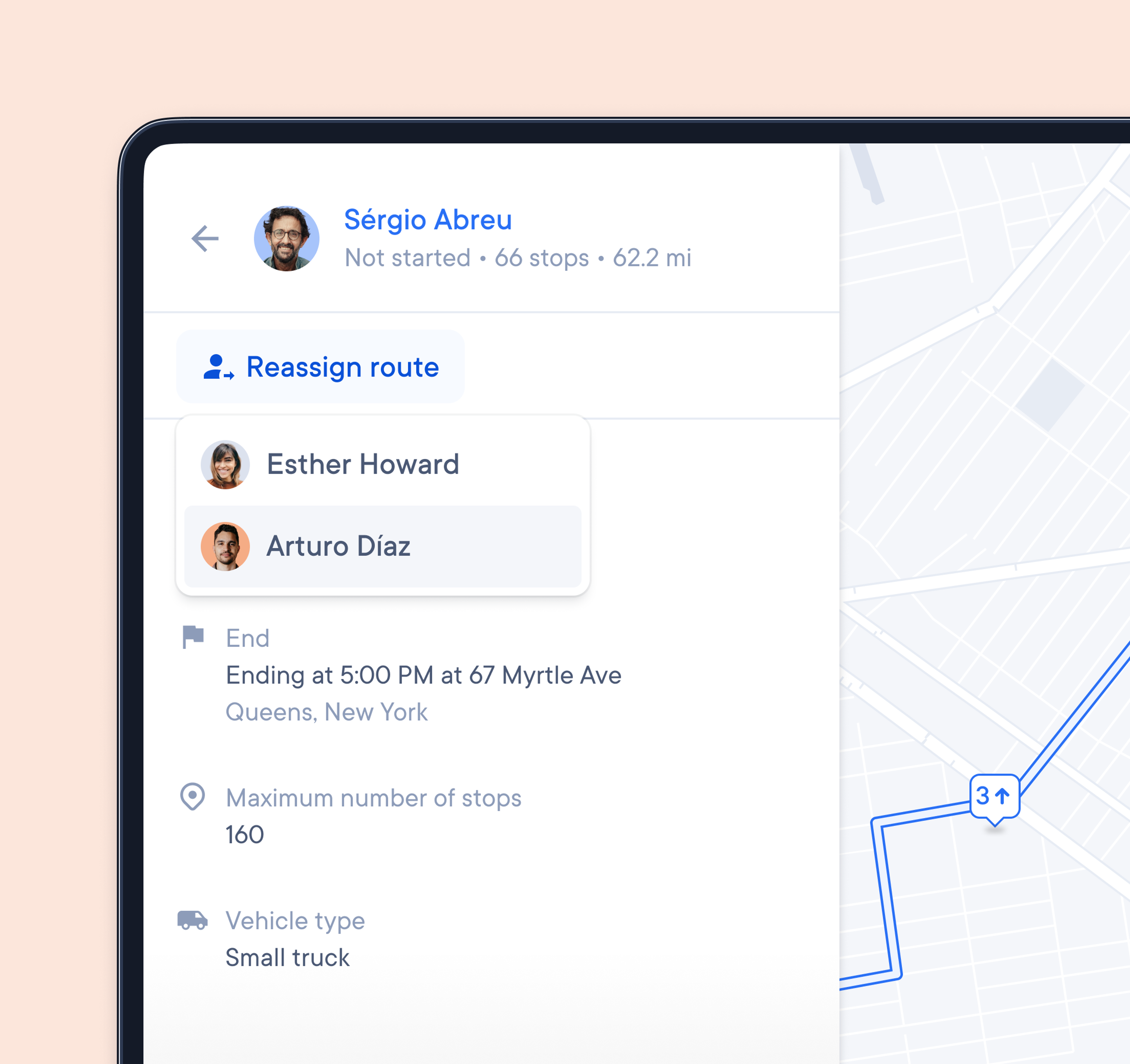

Once the routes are created, dispatchers will assign them to drivers based on several factors, including:

Local knowledge

A driver who knows the backroads of a city can avoid traffic bottlenecks.

Vehicle type

A small van might be perfect for tight urban streets, while a larger truck is better suited for more rural delivery stops.

Delivery urgency

Some packages need express handling, while others allow for more flexible scheduling.

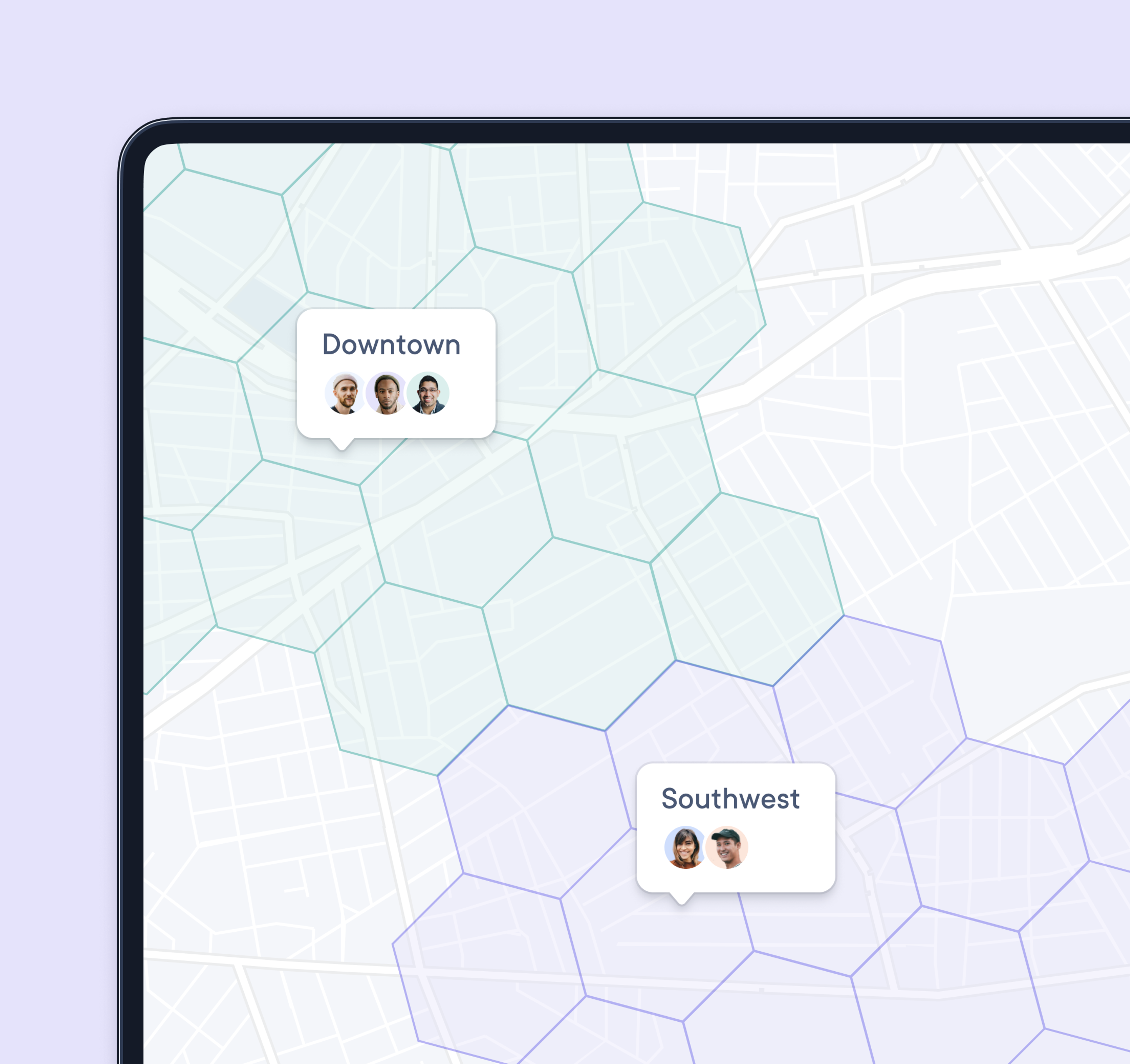

There are some instances where dispatchers will allow their software to allocate routes automatically based on delivery zones. If a delivery stop falls within a specific geographic zone the dispatcher has created, it will be assigned to the route and driver pre-assigned to that zone.

There are also instances where dispatchers will allow drivers to create their own routes using barcode scanning. Every last mile delivery team has their own quirks and ways of working, but the overarching process is the same.

Managing the live routes

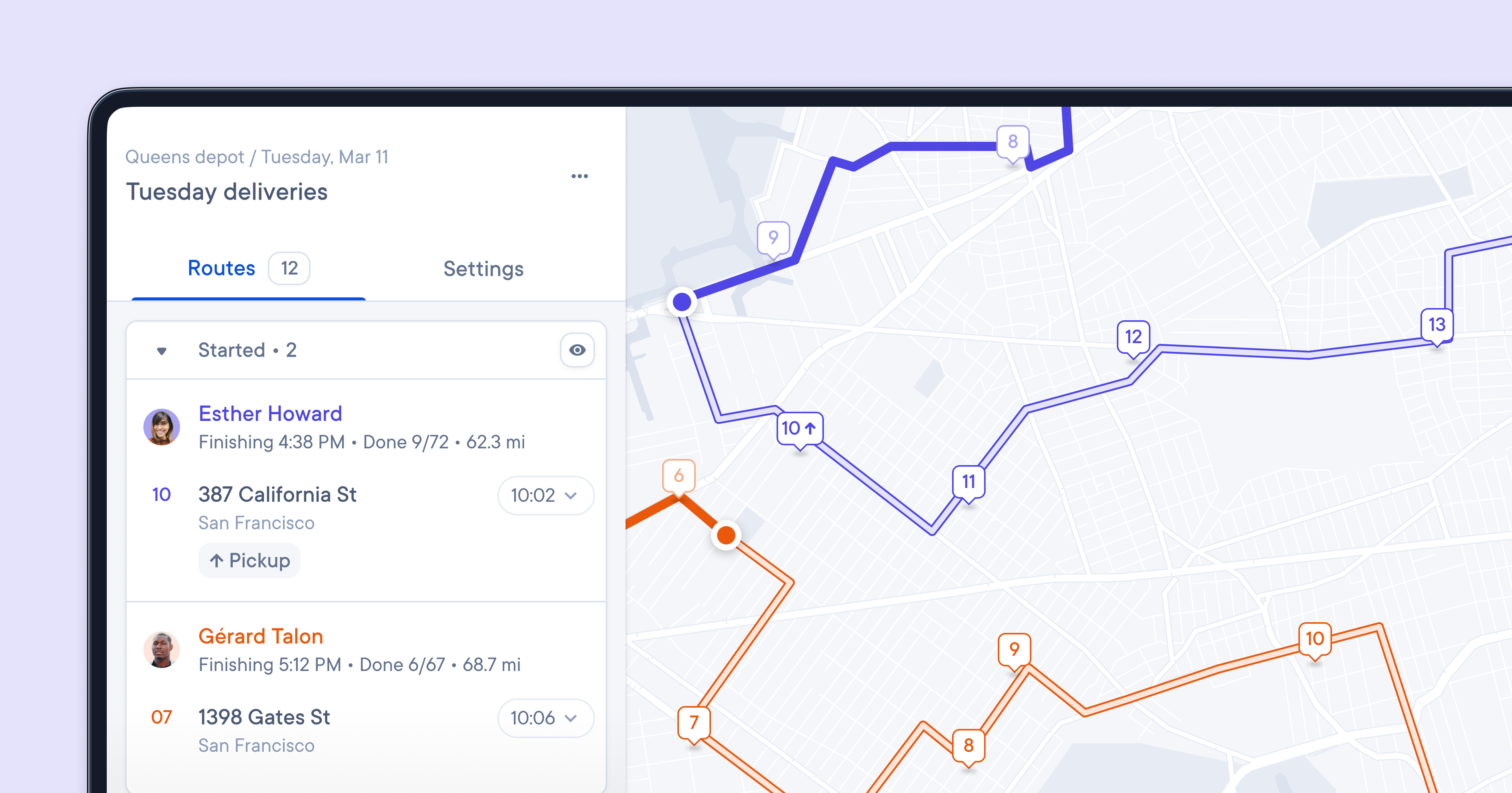

Once drivers hit the road, dispatchers monitor progress and handle any disruptions that crop up. They’ll watch the route's progress on a GPS map from a laptop or device of their choosing.

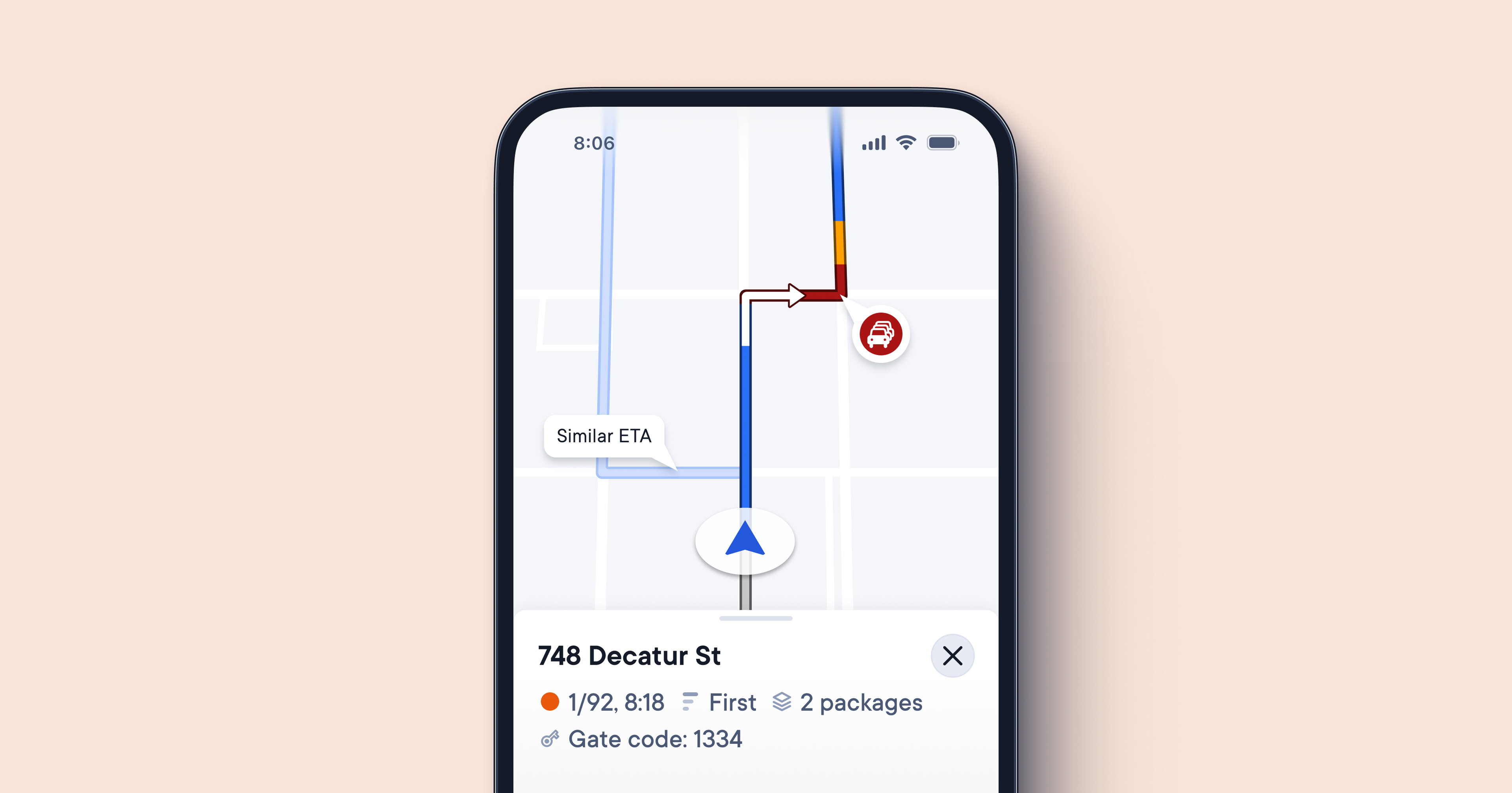

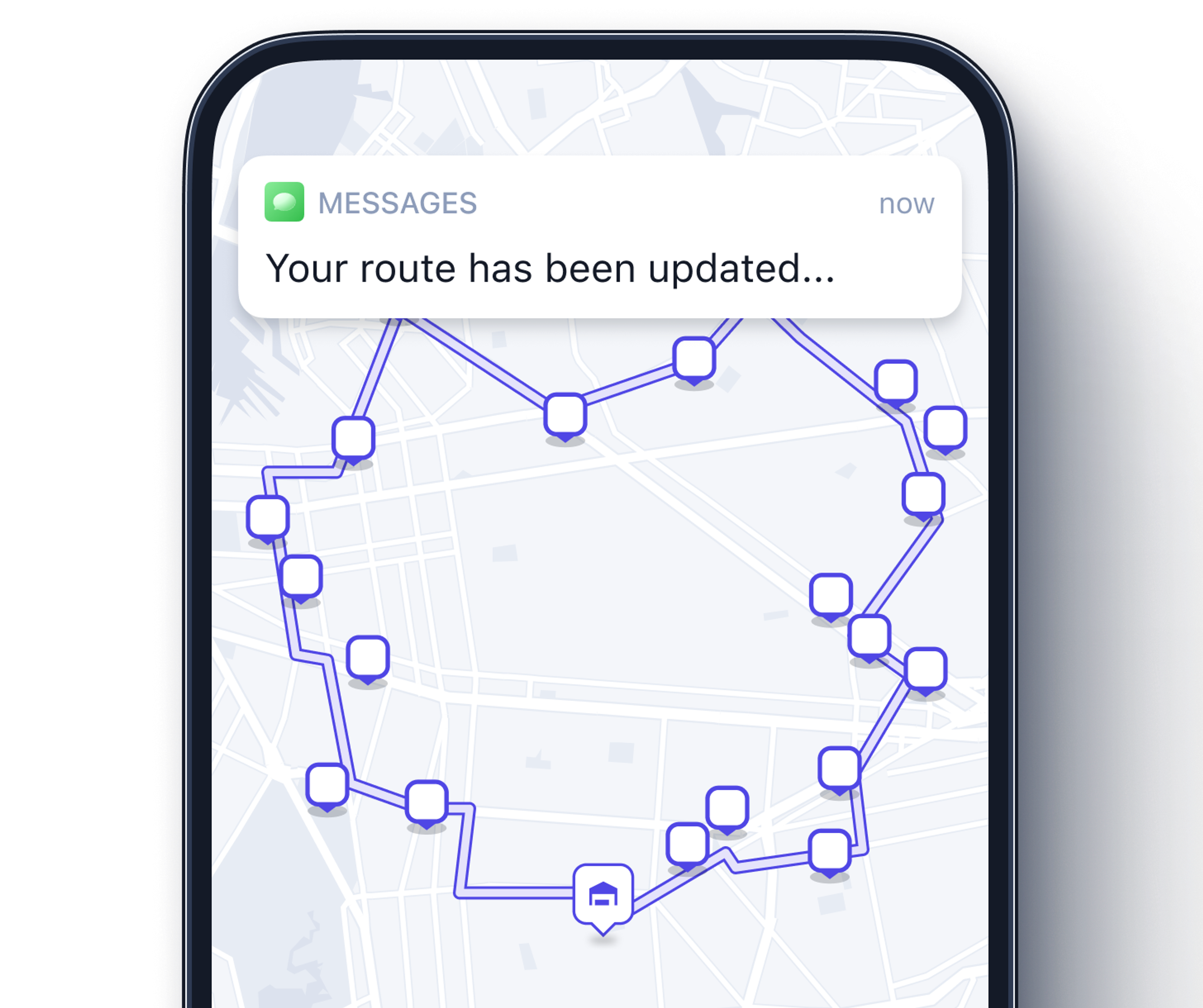

The live GPS tracking helps them see where each driver is and whether they’re on schedule. If someone falls behind due to traffic, vehicle breakdown or too much idling at stops, dispatchers can quickly adjust by rerouting other drivers or contacting customers with updated ETAs.

At this stage, the dispatcher role is focused on problem-solving and removing obstacles. Here’s just a few of the challenges they’ll provide solutions to:

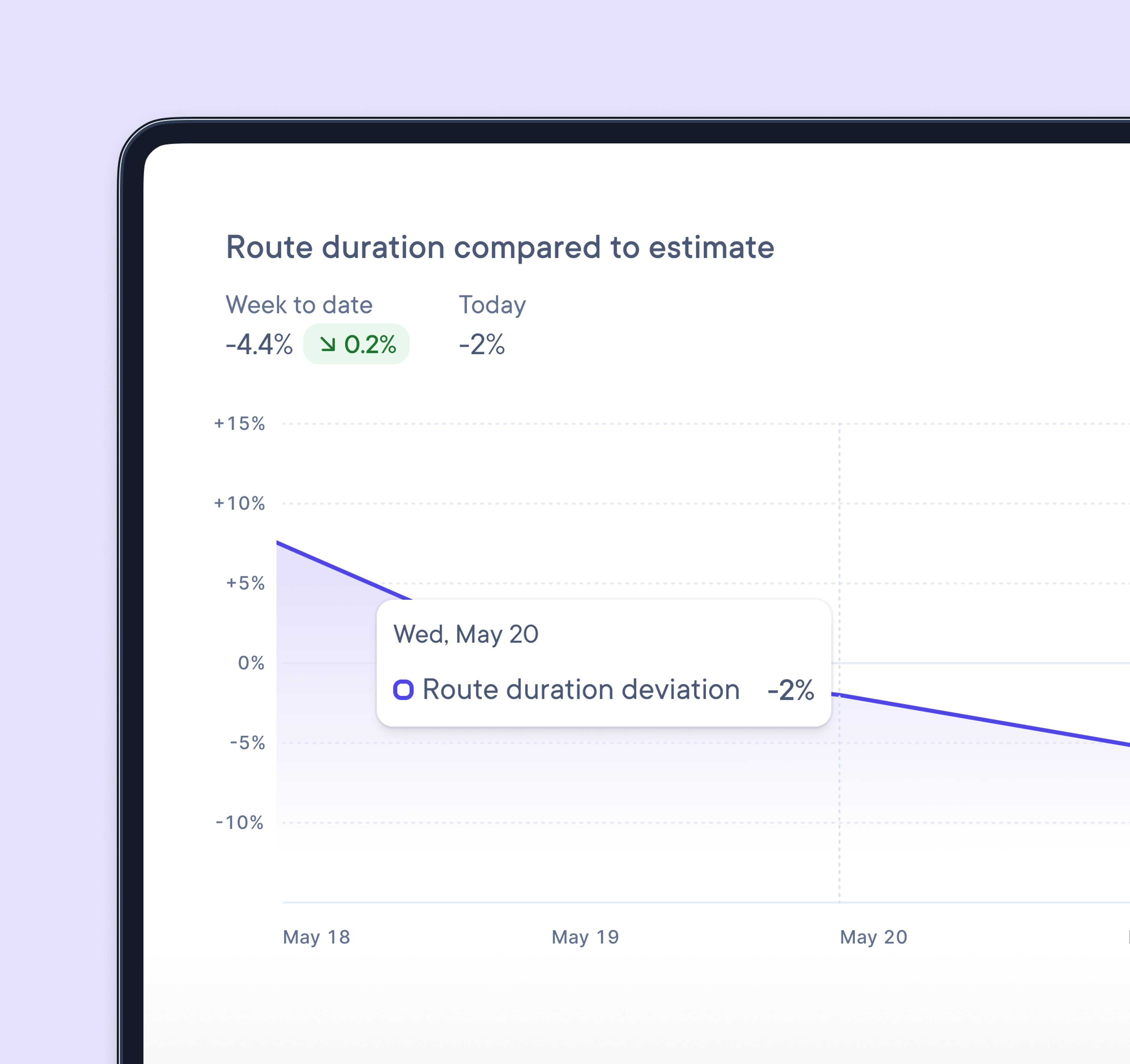

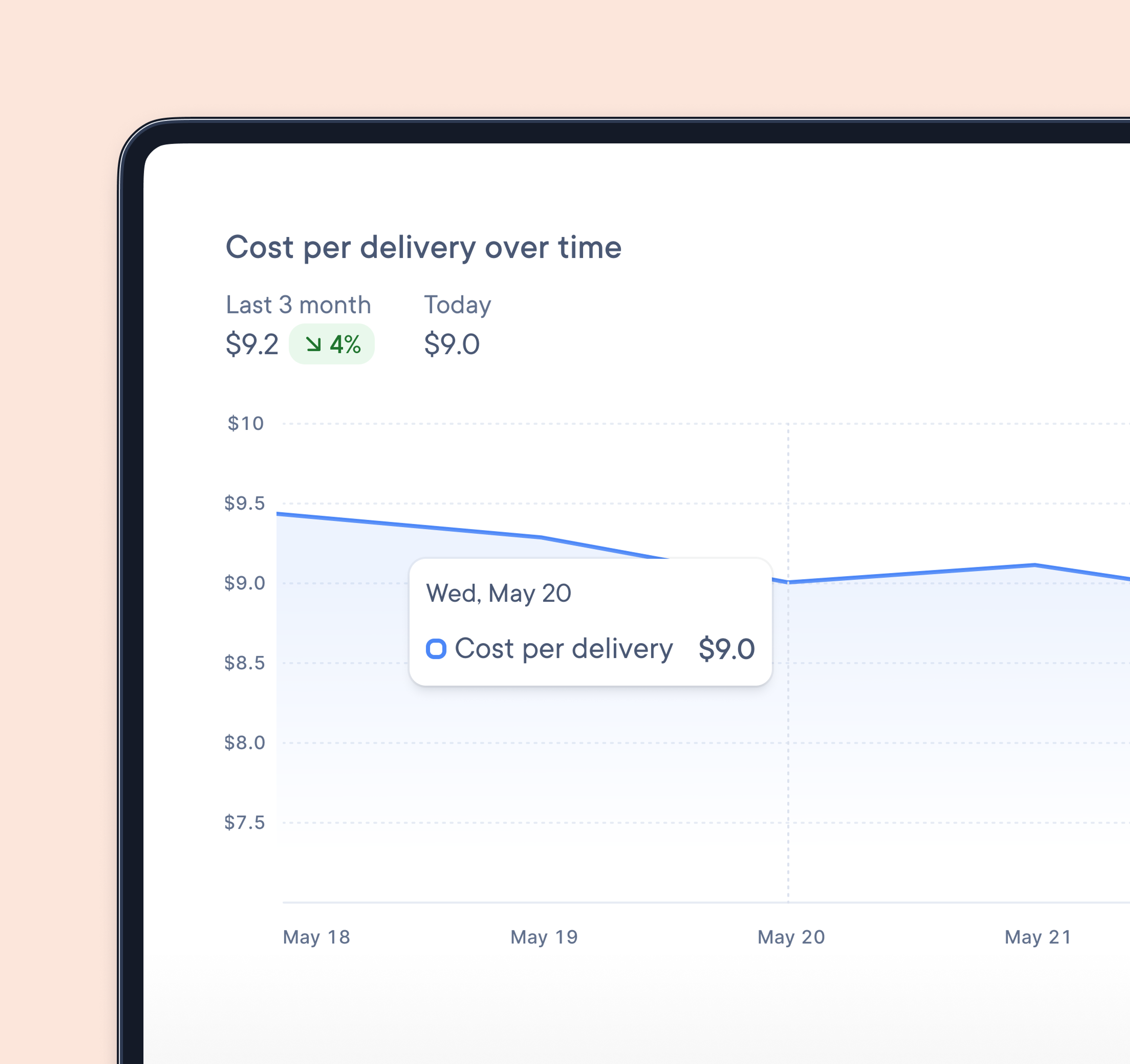

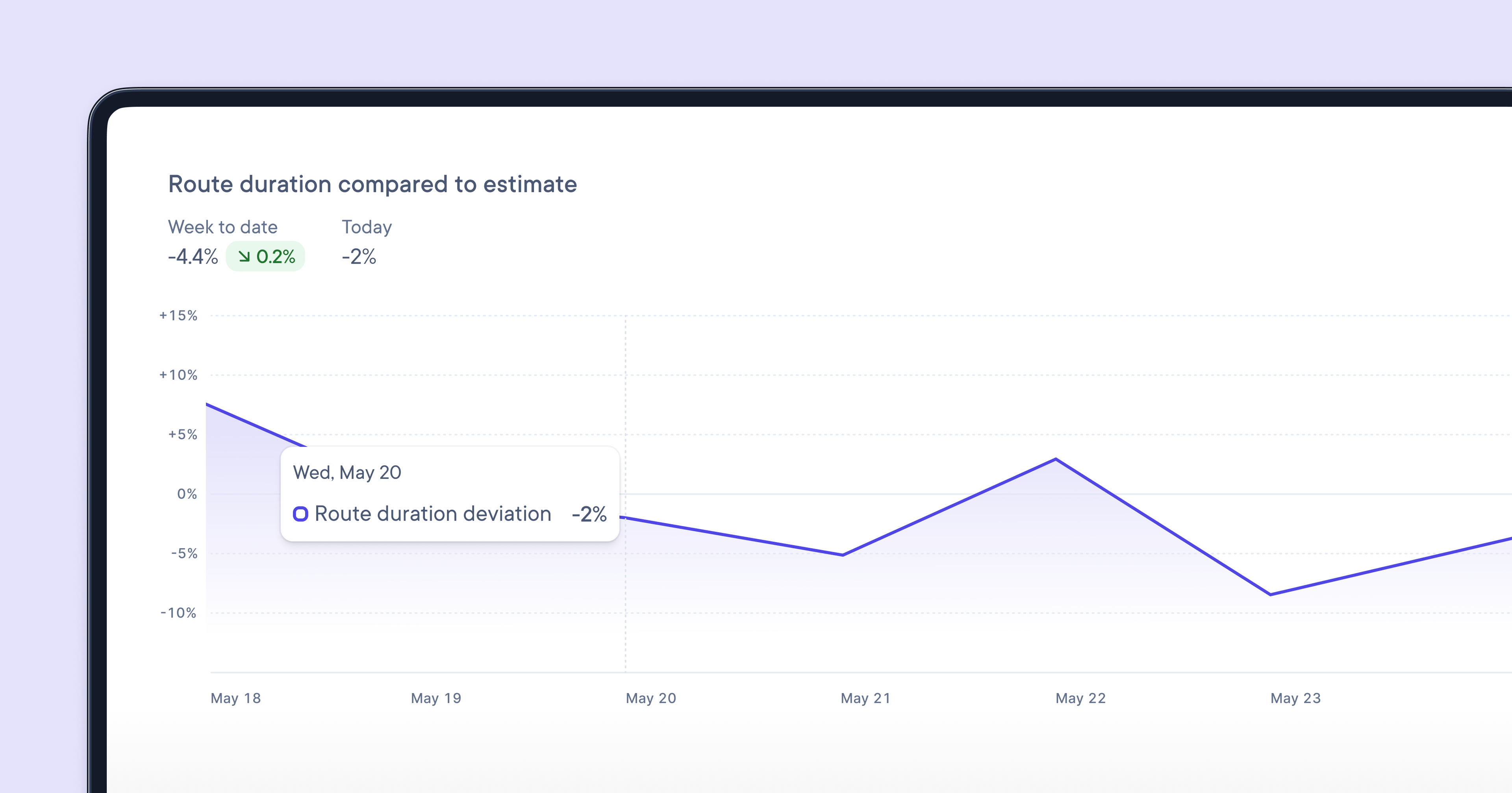

Performance tracking and optimization

Once the last package is delivered there’s still some work to be done. The best last mile delivery teams will likely review key performance metrics to identify areas of improvement. Some of the most important numbers to look at include:

Estimated vs actual route duration

How close were the estimated timelines compared to how long it actually took to complete the route? If they’re way off then there’s an efficiency leak somewhere.

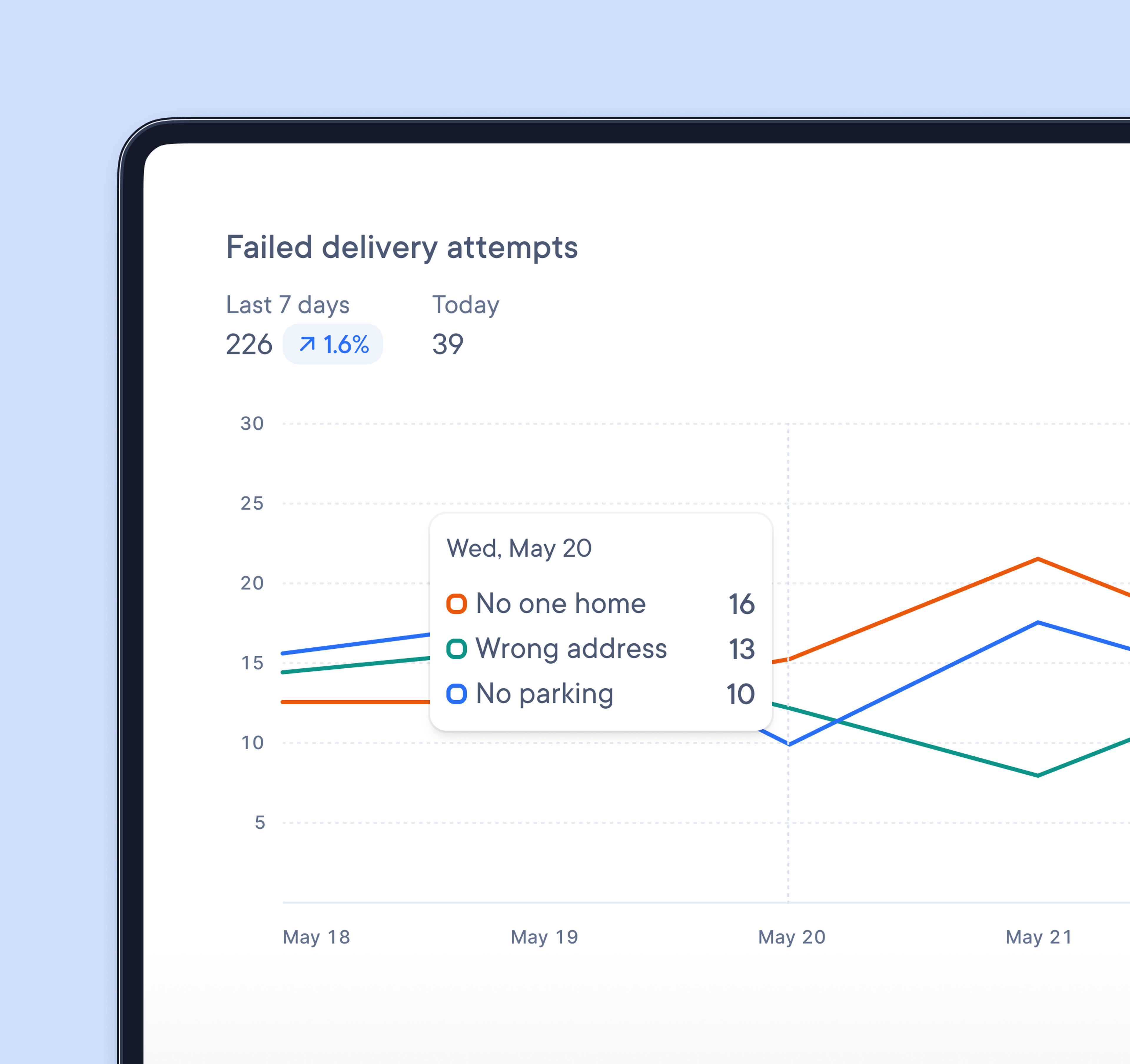

Failed delivery reasons

Do the same reasons appear for the same driver? Is a specific reason higher than others across the fleet?

Average cost of delivery

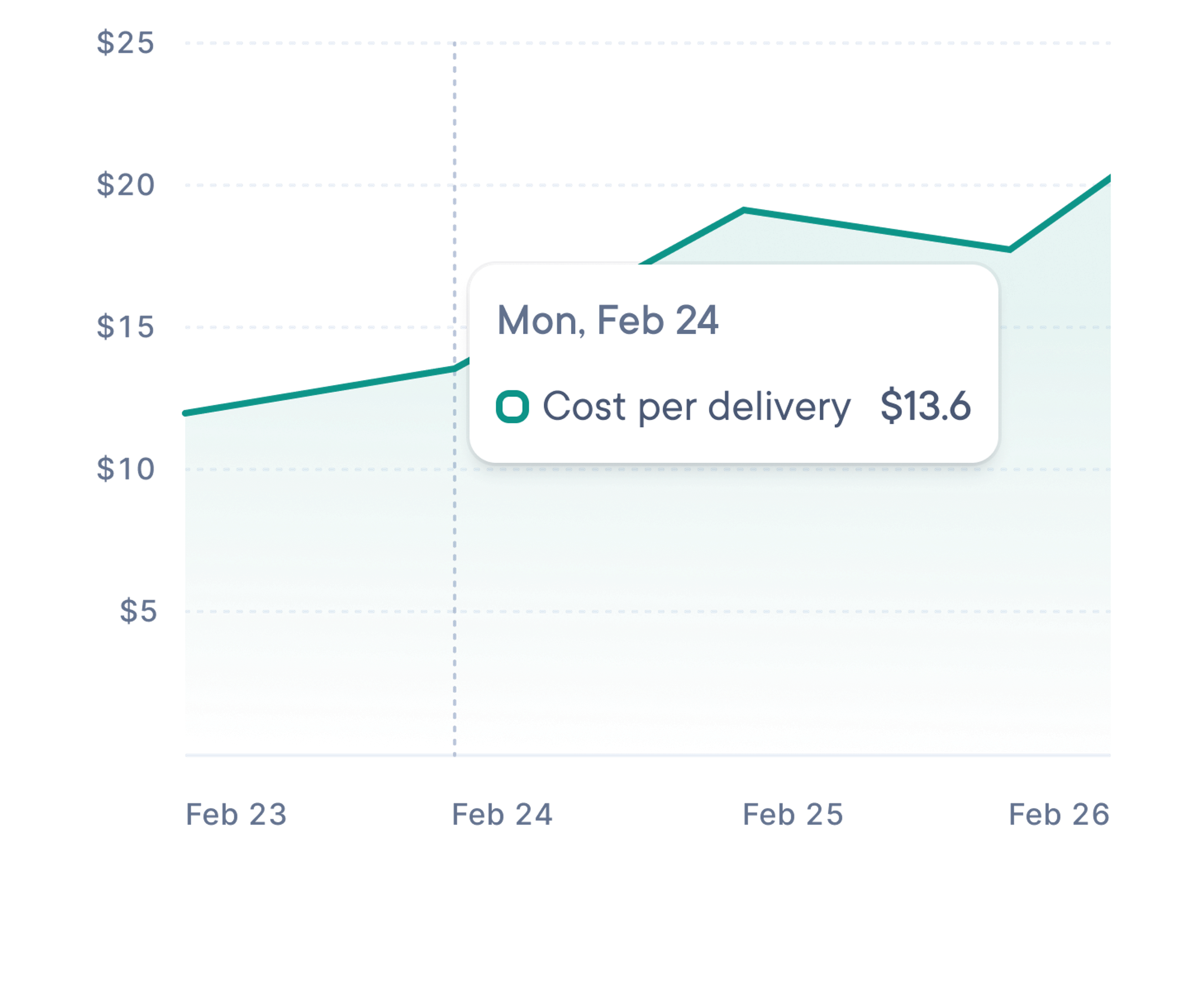

Factoring in fuel and maintenance costs, how profitable or costly was each delivery stop? Is that changing at all?

Completed routes

How many routes were completed that day?

Tracking these numbers is becoming more and more common in last mile delivery. What used to be unmeasurable is now getting increasingly easy to gauge with last mile management software.

A day in the life: drivers

For drivers, there’s a fair amount of on-the-fly problem solving required, but the primary goal is speed and successfully delivering each package. But the tone for the entire day is set in those crucial moments before leaving the depot. A disciplined approach to preparation is what turns a potentially chaotic day into an organized and productive one.

Daily preparation

Drivers begin their work day before they set off on their route. Just like dispatchers, there’s some preparation that needs to be done before the handbrake comes off.

Vehicle inspection

They’ll need to check the fuel levels, brakes, lights, and tires to avoid breakdowns in the middle of their journey.

Loading packages

Experienced drivers know that loading the van in the right order for quick access is crucial to saving time at each stop.

Route familiarization

Reviewing the delivery sequence and identifying areas where their own expertise is better than the optimized route.

Equipment checks

Making sure scanners, delivery apps, and customer contact details are all ready to go.

On the road challenges

Once the driver leaves the depot they’re on their own. They’ll face a mix of navigational, logistical and customer service challenges such as:

Unexpected road closures, rush-hour congestion, and GPS errors can quickly throw a spanner in the works.

Finding legal parking in urban areas near delivery points can be a nightmare, and entry procedures like codes and buzzers can slow things down in gated communities or office buildings.

Some customers expect packages handed directly to them, while others are fine with doorstep drop-offs.

What is the last mile delivery problem?

The “last mile problem” is a common term used to describe the high cost, inefficiency, and complexity of getting packages from the depot to the recipient’s doorstep. The other stages of the supply chain have been refined over the years to be incredibly efficient today, but the last mile is arguably the most important and still has logistics experts scratching their heads.

If we want to get technical, academia defines the last mile problem as “the persistent inefficiency and high cost of final-leg distribution in supply chains, a problem characterized by disproportionate expenses, logistical hurdles, and the need for innovative approaches to improve efficiency.”

In the last mile deliveries separate into thousands of individual drop-offs, each requiring its own route, delivery window, and management. This fragmentation makes last mile delivery unpredictable, resource-intensive, and difficult to live up to customer expectations.

Key factors contributing to the last mile delivery problem

Growing ecommerce demand

Increasing ecommerce demand means even more strain on last mile teams

Rising delivery costs

Rising fuel prices and vehicle maintenance costs keep margins razor-thin

Driver shortages

Labor shortages and high turnover of skilled drivers make resource a headache

We touched on it briefly there, but there are also the unique challenges of urban and rural deliveries that come with their own set of specific challenges.

Why the last mile problem is getting harder to solve

The challenges of last mile delivery haven’t just increased, they’ve been fundamentally reshaped by two major market forces:

The Amazon effect

Amazon has set the bar incredibly high for fast, cheap, and highly efficient delivery. Next-day and even same-day delivery are no longer premium services, they’re just a given for today’s recipients. This has forced courier companies and other last mile delivery teams to meet near impossible speed demands without the reprieve of lower operational costs.

The Shopify effect

Now let’s look at it from the seller’s point of view. Shopify and similar platforms have made it possible for any business to sell anywhere, increasing the complexity and demand of last mile delivery. Retailers are shipping to customers across cities, countries, and continents, requiring courier networks to handle a staggering volume of deliveries which will only increase.

Breaking down the challenges of last mile delivery

We’ve spoken a lot about the challenges of last mile delivery, and of course we’re not here to be the harbinger of doom. This industry is projected to grow from $197.0 billion in 2025 to $352.7 billion by 2035. It is an incredibly dynamic, fast-growing and exciting industry, but before we can discuss the solutions it makes sense to understand the pain points.

Why last mile is the most expensive stage

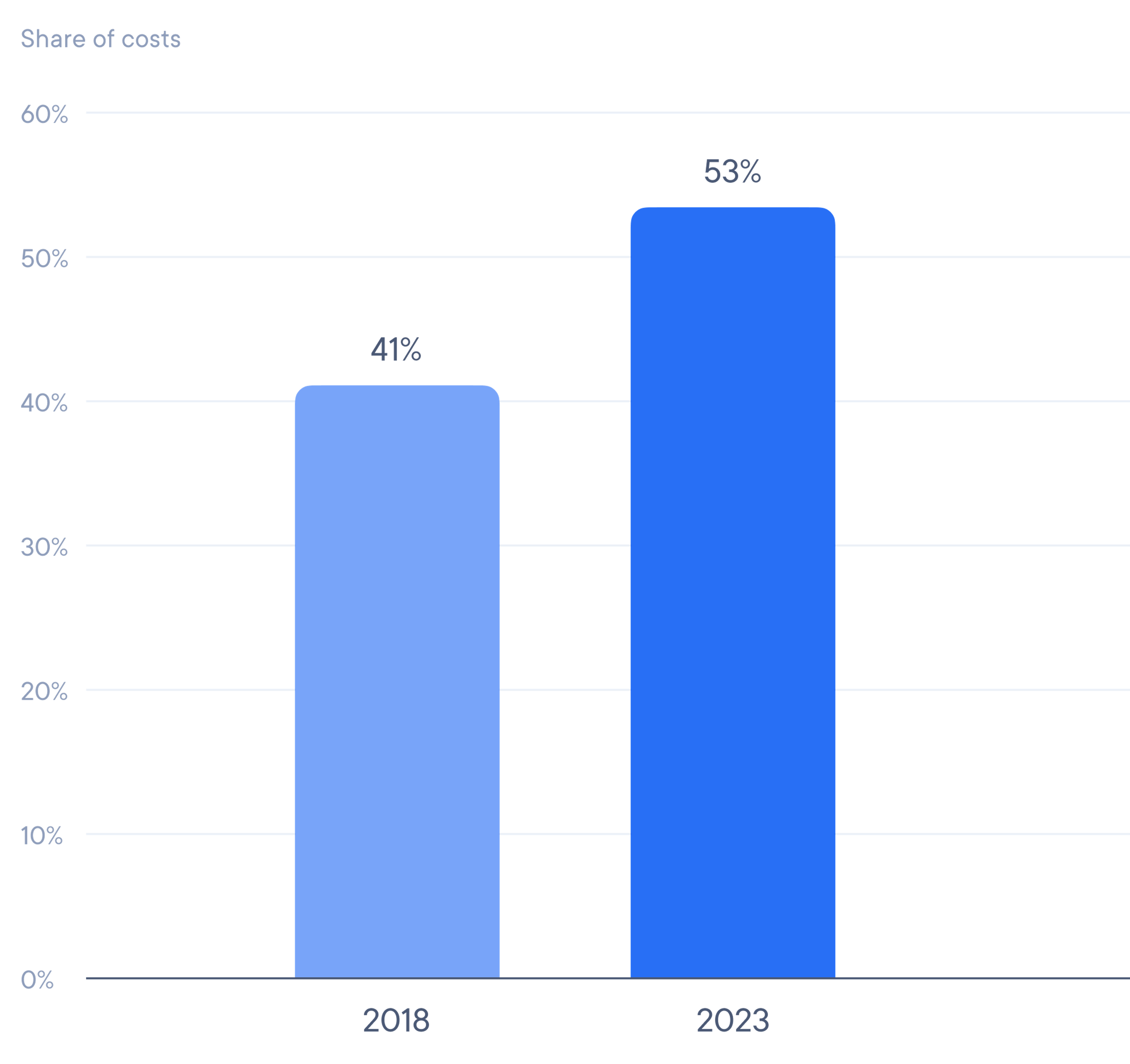

53% of shipping costs

Last mile delivery accounted for 53% of total shipping costs in 2023, up from 41% in 2018.

Rising trend

That number is expected to be even higher in 2025 as costs continue to rise.

Last mile delivery cost factors

These costs aren’t just operational though, they extend to failed deliveries, sustainability efforts, and investments in technology to stay competitive. Let’s quickly look at the cost factors in last mile delivery:

Fuel expenses

Covering volatile gas prices and consumption from inefficient routes.

Vehicle maintenance

Regular servicing for brakes, tires, and engines to prevent costly breakdowns.

Re-attempted deliveries

The added mileage and labor costs from every failed delivery attempt.

Customer support overhead

Staffing resources needed to handle tracking requests and customer inquiries.

Regulatory compliance costs

Meeting special requirements like temperature control or secure handling.

Returns and refunds

The cost of reverse logistics, including processing and restocking items.

Traffic, failed deliveries and urban congestion

Unpredictable external factors

Traffic congestion, poor address accuracy, and unforeseen delays.

Delivery mistakes

75% of package recipients report delivery issues like missed drop-offs, lost packages, or incorrect ETAs.

City chaos

In urban areas the restricted parking, delivery access rules and stop-start drop-offs slow drivers down tremendously.

Rural reach

In rural areas the long distances between stops and infrastructure limitations make routing and cell coverage tricky.

More deliveries, more emissions

More vehicles in the cities

Urban delivery traffic alone could increase emissions by 32% by 2030.

Pricey electric options

Of course, electric delivery vehicles (EVs) are the better option. They can reduce both emissions and costs by 25-30%, but they also require large investments.

Outdated systems and integration challenges

Old frankenstein systems

A lot of courier companies are still using pen and paper, old systems, or a patchwork of disconnected tools.

Integration misconceptions

Tools that feature live tracking and smart routing make delivery teams more efficient, but adoption is slow as many delivery teams see it as a cost, rather than a cost-saver and think integration will take months which isn’t true.

Resistance to change

Many last mile delivery teams will stick with manual processes because that’s just the way it’s always been, even if technology can increase the bottom line.

The push for faster delivery

30%

Same or next day delivery. 30% of shoppers expect same-day delivery and those expectations aren’t going in reverse.

61%

Willing to pay for speed. 61% of customers will pay extra for faster shipping but this revenue is consumed by rising operational costs

85%

Expect top-tier service. 85% of consumers won’t repurchase after a bad delivery experience.

How technology is helping couriers solve last mile challenges

Planning helps, but managing deliveries smoothly requires the right tech. Tools that include route optimization, real-time tracking, and automated dispatching makes life a ton easier for dispatchers and drivers. Delivery teams that adopt these tools deliver faster, have lower costs, and stay on top of their growing demand.

What is last mile management software?

Last mile management (LMM) software is the one-stop-shop for managing all aspects of the last mile delivery process.

It’s designed to reduce manual labour, save both dispatchers and drivers hours of time and in doing so, increase profit for the delivery business.

Rather than juggling spreadsheets, phone calls, and manual planning, it gives dispatchers, drivers, and customers one place to manage the entire last mile.

The best platforms are built for flexibility and control, so courier companies can shape them to fit the way they work, whether that’s handling high-volume ecommerce orders, scheduled B2B runs, or on-demand jobs.

Core features of last mile management platforms

Live GPS tracking

Dispatchers can monitor every driver’s location on a live map, helping them stay ahead of delays, reroute drivers, and make sure deliveries are completed on time.

Dynamic customer notifications

Automatically send branded SMS or email updates to let customers know when their delivery is on the way, delayed, or complete.

The benefits of route optimization software for last mile delivery

Route optimization software is a term used interchangeably with last mile management software. It uses an algorithm that takes the guesswork out of route planning by factoring in things like:

Live traffic data to avoid congestion and delays

Vehicle capacity to fit bulky items correctly

Driver skills to match jobs with the right driver

Custom time windows to ensure on-time delivery

Route optimization gives you full control of the last mile delivery process once the drivers have hit the road. You can:

In short, route optimization software makes last mile delivery faster, smoother, and far less stressful. Instead of reacting to problems as they come up you can stay ahead of them.

Easier adjustments

If plans change last minute, dispatchers can easily reassign stops or update routes without rebuilding everything from scratch.

Fewer miles traveled

Drivers are on quicker routes so they save on fuel and vehicle maintenance costs.

Less wasted time

Drivers follow efficient routes that avoid backtracking and keep them moving smoothly from stop to stop.

What is a route optimization algorithm?

Think of this algorithm as a super-smart GPS. Instead of just showing directions, it looks at all your stops plus things like traffic, delivery windows, priority orders, tolls, and road restrictions to map out the most practical and efficient route.

Example of how last mile management software is used in last mile delivery

Hungarian logistics company CarryAll used to spend hours manually adjusting routes. After switching to Spoke Dispatch, they saved three hours a day, which is time that could be put to better use on higher-value tasks like customer service and scaling operations. See how Spoke Dispatch can save you 3+ hours a day. Try it for free.

How last mile management software can reduce costs

There’s a common theme in this guide. Last mile delivery is the most expensive part of the supply chain, and lowering costs is a primary focus for delivery teams. Fuel, labor, vehicle upkeep and failed deliveries all eat into margins. For courier companies working on tight budgets, even small inefficiencies can make a big difference to profitability.

The good news is there are ways to bring these costs down without slowing deliveries or letting customers down. With the following strategies, couriers can cut waste and keep service levels high. It doesn’t have to be one or the other.

Planning routes by hand takes hours and still leaves room for mistakes. Route planning tools handle it in minutes, picking the fastest paths using live traffic, road closures, and delivery priorities.

If a driver calls in sick or traffic grinds to a halt, the software adjusts instantly. That means less wasted fuel, fewer overtime hours, and routes that actually work at scale regardless of whether you’re handling 10 stops or 5,000.

Get more bang for your buck by being smart about how you pack your vehicles. Vehicle capacity features in last mile software show how full each truck is by weight, volume, or item count, so you avoid unsafe or uncompliant loads. And instead of sending half-empty trucks or scrambling to stack boxes like Tetris at the last minute, you can plan ahead and use every inch of space. This cuts down on trips, lowers fuel costs, keeps drivers happy with balanced loads, and gives you confidence when promising delivery times.

When you're smart about managing delivery times, you can cluster more stops in the same area. Instead of your drivers zigzagging across town all day, you'll help customers pick time slots that make sense for your routes. By grouping nearby deliveries into similar time windows, your drivers spend less time between stops and more time actually delivering. This means lower fuel costs, less driver frustration, and the ability to handle more deliveries without adding trucks or staff.

Missed deliveries are expensive and the bane of the industry. Every failed stop wastes fuel, driver hours, and often leads to frustrated customers. Last mile management software helps cut those losses by keeping recipients informed with live SMS or email alerts and ETAs. If they can’t be home, recipients can quickly reschedule or choose a safe drop-off spot through a link or on the portal. And when the parcel is delivered, drivers can capture proof with a photo or signature so there’s no doubt about where it ended up. Fewer missed stops mean fewer wasted miles and less time spent on dispute calls.

The consequences of poor last mile delivery

A last mile delivery operation that has efficiency leaks will eat into profits and frustrate customers. If clients lose trust because of late or missed packages, winning them back isn’t going to be easy and competitors who consistently deliver on time will have the upper hand.

The real cost of getting last mile delivery wrong

Delivery compliance gets trickier for businesses operating in more than one country. Different regions have different regulations around data security, delivery timeframes, and emissions.

Wasted time, fuel, and resources

For every delivery that fails the business will lose money. Research shows that up to 20% of packages don’t make it on the first attempt, costing billions in losses across the industry. On average, one failed delivery costs about $17 when you factor in fuel, driver time, and handling. Multiply that by thousands of stops a day, and the impact on your bottom line becomes clear fast.

Slow, missed, and inaccurate deliveries cost you

Customers expect fast deliveries, but they also expect reliable deliveries. If their package is late, dropped at the wrong address, or mysteriously lost in transit, they get frustrated. Note the earlier stat about how many customers don’t return to a company after a bad delivery experience and you can see where we’re going with this. The thing to remember here is that speed is just one part of the last mile delivery puzzle. Customers also want visibility. They expect real-time tracking, accurate delivery windows, and the ability to reschedule or reroute if needed. Even one missed or late delivery can prompt a customer to go elsewhere, losing you a valued buyer for good.

The hidden costs of delivery mistakes

Every failed or delayed delivery has a price. If we take the research above, that price is approximately $17.20. Sometimes, it might be much higher than that. Last mile delivery companies are responsible for eating the costs of rescheduled drop-offs, refunded orders, and even time spent handling complaints. If enough customers ask for refunds or replacements because of poor delivery, your margins will shrink very quickly. And we’re not talking about one-off losses here. Poor last mile execution leads to long-term revenue decline. You lose out on repeat sales when customers stop ordering with you because they lost trust in the delivery process.

What happens if you fail to meet delivery standards?

Many industries have strict service level agreements (SLAs) and compliance requirements. For example, delays or mishandling of deliveries to do with medical supplies, food, or regulated goods can have pretty nasty legal consequences. Staying compliant could involve couriers and retailers needing to meet specific delivery timeframes, temperature control standards, or proof-of-delivery requirements. If you don’t meet these standards you can get hit with penalties or even lose contracts.

Again, not meeting these requirements can lead to… you guessed it, more fines and lost business opportunities.

It really does come down to having the strategies, technology, and infrastructure in place to make the final mile engine purr. Because last mile delivery doesn’t have to be a constant struggle. In fact, it can become a powerful differentiator that secures customer loyalty, reduces costs, and sets your business apart in a crowded market.

Why last mile delivery is so important to get right

Last mile delivery might technically be “just another step in the supply chain”, but it’s the most visible part of the entire process, for the end customer, anyway.

Really, when you think about it, last mile delivery completes the supply chain. It closes the loop, so to speak. But, because it deals with individual deliveries instead of bulk shipments, it’s also the most unpredictable.

The high stakes of last mile delivery

You can have the most efficient warehouse in the world, but if the final delivery is late, expensive, or unreliable, that’s all the customer will remember.

One bad delivery can lose a customer

In fact, 80% of consumers won’t buy again after a bad post-purchase experience.

Missed expectations mean lost revenue

And because last mile delivery is one of the biggest factors in that experience, getting it wrong means losing customers and revenue.

Gaining a competitive edge in last mile delivery

While most companies see last mile delivery as a necessary headache, smart businesses are turning it into their secret weapon.

When you nail your last mile delivery (e.g. making it fast, reliable, and transparent) you end up creating confidence, trust, and a reason for customers to choose you over competitors.

Every successful delivery is a chance to reinforce your brand's promise. Every on-time arrival builds trust. Every easy-to-track package shows customers you value their time. In a market where everyone offers similar products, exceptional delivery becomes your standout feature.

Excellence in last mile delivery creates a competitive advantage that's hard to copy. While competitors struggle with late deliveries and frustrated customers, businesses that master last mile delivery enjoy:

Organic growth

Word-of-mouth recommendations (free marketing!)

Better margins

Higher margins from customers willing to pay for reliability

FAQs

Last mile delivery is the final step in the logistics process, where goods are transported from a distribution hub to the customer’s doorstep. It’s also the most important and most challenging part of the supply chain, and contributes the most to the overall customer experience. A good last mile delivery operation gets packages to recipients on time without issue, whereas those that regularly have delays, inefficient manual processes and bad package visibility will eventually lead to loss of clients.

The Shopify and Amazon effects have sent customer expectations through the roof. But this is also in tandem with calls for faster shipping, more order demand, higher levels of urban congestion and regulations, and different sustainability requirements. If you add that to the difficulties of keeping skilled drivers, the last mile is not for the faint of heart. Luckily, there are plenty of strategies courier companies are using that turn the final leg from cost centre to revenue driver.

The first-mile, where the goods will begin their journey from the supplier or manufacturer to the fulfillment center. Once there, they’ll be stored, sorted, packed and prepared for the next leg which is the middle mile. The mid-mile is where the goods go from fulfillment centers to the local depots or distribution hubs. Then, the last mile is of course the goods going from the depots to the recipients doorstep.

Using route optimization software to create more efficient routes is a solid first step. This means you’re taking control of your fuel and maintenance costs, and ensuring you’re not losing money with routes that don’t make sense. Plus, your dispatcher has now saved X amount of hours by not manually planning routes and handing out printed manifests. Next, you need to improve the transparency and visibility of your last mile operation. By using the live tracking and delivery notification functionality on your software, you’ll be able to keep clients and recipients in the loop automatically. The outcomes here are less failed deliveries and a better customer experience. This additional free time could be spent on strategic decisions like perhaps offering a different type of delivery service like next-day or same-day delivery. Or perhaps your team of drivers is now in a position to deliver more stops. As you can see, optimizing just a few stages of the process can begin a domino effect of positive growth which can set you apart from competitors.

First you’re looking at fuel expenses which can easily stack up if the delivery business is covering them instead of the driver. Then there’s the labor wages, whether your drivers are on a salary or a per stop payment model. Vehicle maintenance if you own your own fleet of vans for example is another large expense, though many delivery businesses will subcontract drivers and they will cover their own vehicle expenses. Failed deliveries are a big one, as we’ve established each failed delivery costs $17 on average. Last mile management software is another line item that many delivery businesses will initially perceive as an expense, but given how much money it can save across all of the aforementioned costs it is better placed as a revenue driver. Also customer expectations for free or same-day shipping will also put a strain on last mile delivery costs.

Any industry that needs goods delivered to a customer’s doorstep. The Ecommerce industry is by far the most dominant industry, and this is followed by grocery, meal and restaurant delivery. Then you have pharmaceutical or medical deliveries, car parts, B2B and legal documentation industries.

The last mile is often the only part of the supply chain where the customer comes into direct contact with your business. That final handoff shapes how they see both the retailer they ordered from and the courier who delivered it. Get it right, and you leave a lasting positive impression as it’s fast, reliable, transparent deliveries that build trust and satisfaction. Mess it up with delays, missed time windows, or bad communication, and customers will let you know with negative reviews or by taking their business elsewhere.

Same-day delivery is when you’ll get your package on… you guessed it, the same day as when you ordered it. Next-day delivery, as you might imagine, is guaranteed delivery the day after you place your order. On-demand delivery is a tad different, basically this means the delivery happens as soon as possible after the order is placed, which could be within minutes or hours and trackable via an app.

At the end of the day, delivery teams care about a few big things: planning routes quickly, knowing those routes actually make sense on the road, and being able to see drivers moving in real time. You also don’t want to spend hours typing in addresses, so bulk uploads, which usually through a spreadsheet or API, are a must. A good LMM software also keeps dispatchers and drivers in sync with connected apps. Add in live tracking, proof of delivery, customer notifications, barcode scanning, and some solid analytics, and you’ve basically got everything you need to keep operations tight and customers happy.

Although technology like drones and autonomous vehicles seem to be grabbing all the headlines, the trends of the future are more focused on practical efficiency. A big trend for the future is demand aggregation, which is the consolidation of orders to reduce costs and improve vehicle capacity efficiency. So much efficiency is being lost by vans hitting the road with only 25-50% of the vehicle packed, so businesses are grouping deliveries and partnering with third-party carriers to optimize the fulfillment stage. Another trend is the rise in micro-fulfillment centers, meaning smaller warehouses closer to customers, cutting delivery times and costs. Another trend might be to allow recipients more control over their delivery, for example more rescheduling, rerouting, and precise time windows to reduce failed attempts.